Choosing the suitable plumbing pipe fitting types is crucial for plumbing systems, pipeline industries, and gas or water supply companies. Among many options, threaded pipe fittings have earned a solid reputation for their simplicity, reliability, and cost-effectiveness. In this article, we'll dive deep into the key advantages of threaded pipe fittings, explaining why they remain a go-to choice in many industries.

1. What Are Threaded Pipe Fittings?

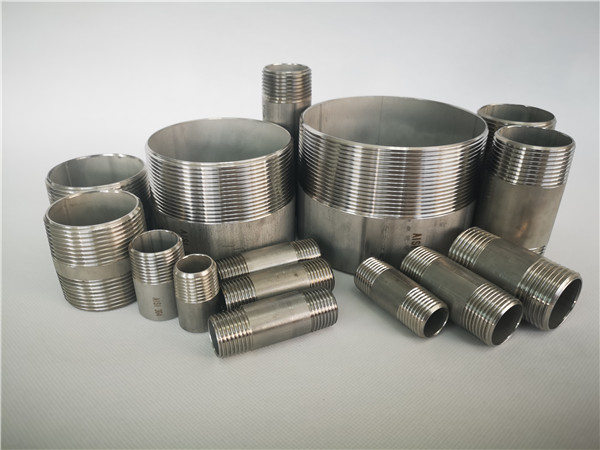

Threaded pipe fittings are connectors connected to two pipe sections using external (male) and internal (female) threads. They are in plumbing, natural gas distribution, fire protection systems, and industrial applications.

Popular materials for threaded fittings include carbon steel, stainless steel (304/316), galvanized steel, and brass. These fittings are particularly common in smaller pipe diameters, typically under 4 inches.

-

Easy Installation and Removal

One of the significant advantages of threaded pipe fittings is the ease of installation. Unlike welding or soldering, which require skilled labor and specialized equipment, threaded fittings only use simple hand tools like pipe wrenches.

No welding required: This saves labor costs and speeds up the process.

Ideal for repairs: If a section needs replacement, fittings can be unscrewed and replaced without cutting the pipe.

Perfect for tight spaces: Threaded plumbing pipe connectors are easier to install in confined spaces than welding.

-

Cost-Effective Solution

In terms of both labor and material costs, threaded fittings offer significant savings:

Lower installation costs: Since no welding is needed, labor is quicker and cheaper.

Reduced equipment expenses: Pipe thread fittings do not need expensive welding machines or protective gear.

Affordable material: Common materials like galvanized steel and black iron pipe fittings are budget-friendly.

They make threaded pipe fittings ideal for budget-conscious projects or temporary setups.

-

Strong and Reliable Connections

When properly installed, threaded pipe fittings provide strong mechanical connections that handle moderate to high pressures.

Stainless steel pipe fittings (especially 316) offer excellent resistance to corrosion and are suitable for harsh environments.

Galvanized steel fittings are ideal for outdoor or industrial applications where rust prevention is needed.

Threaded connections are leak-resistant when sealed correctly with Teflon tape or pipe dope.

-

Flexibility in Design and Application

Another main advantage is flexibility:

Wide range of types: There are various types of pipe fittings available—elbows, tees, couplings, bushings, plugs—all in threaded options.

Easy system modification: Threaded fittings are simple to expand, reconfigure, or dismantle piping systems.

Compatibility: Threaded fittings work with many pipe materials, such as steel pipes, brass pipes, and even PVC (with threaded adapters).

-

Suitable for Low to medium-pressure systems

Threaded pipe fittings are perfect for low and medium-pressure applications:

Water distribution systems

Compressed air networks

Natural gas supply lines

Fire sprinkler systems

However, welded or flanged connections are more appropriate for extremely high-pressure systems or added safety-critical installations.

-

Minimal Maintenance Needs

With proper installation and sealing, threaded pipe fittings are durable and require little maintenance:

Periodic checks: Inspect for leaks or corrosion.

Quick fixes: Usually address any issue without extensive downtime or specialized equipment。

They make threaded fittings an excellent choice for systems where low maintenance is a priority.

2. Best Practices When Using Threaded Pipe Fittings

While threaded fittings have many advantages, here are a few tips for best results:

Use thread sealant: Always apply Teflon tape or pipe thread sealant for a leak-proof joint.

Avoid over-tightening: This can crack fittings or deform threads.

Choose the right material: Use stainless steel or brass instead of black iron for corrosive environments.

3. Conclusion

Threaded pipe fittings offer an unbeatable combination of simplicity, affordability, and reliability. Whether setting up a home water system, designing an industrial gas pipeline, or maintaining a commercial building's fire protection network, threaded fittings are a wise choice.

Choosing high-quality fittings—like stainless steel couplings, galvanized steel connectors, or black pipe fittings—from a reliable supplier can ensure long-lasting performance.

If you're looking for efficient, cost-effective, and flexible pipe connection solutions, threaded pipe fittings are worth considering.

Need top-quality threaded fittings at factory-direct prices? We are an experienced manufacturer offering a full range of pipe connectors with fast delivery and customization options. Contact us today to get a free quote!