Hebei Sanvo is one of the quality pipe fittings manufacturers and suppliers in China and specializes in the production of steel pipe nipples, steel pipe coupling, stainless steel threaded pipe fittings, etc. These steel pipe fittings are made of carbon steel or stainless steel. The main difference between the steel pipe nipple and steel pipe coupling is the thread connection types.

The pipe nipple has one male threaded end or both threaded ends, and the pipe coupling has female threaded ends.

1. What Is A Pipe Nipple?

A threaded pipe nipple is a short piece of pipe usually with male threads at both ends or one end for connecting two other pipes or fittings. The threads at two ends can be the same or different types, such as NPT thread to BSP thread nipples also exist. And it is one of the most popular categories of pipe fittings.

The length of the pipe nipple is usually specified by the overall length of threads. It may have a hexagonal section in the center for the wrench to grasp (sometimes referred to as a “hex nipple”), or it may simply be made from a short piece of pipe (sometimes referred to as a “barrel nipple” or “pipe nipple”). A “close nipple” has no unthreaded area; when screwed tightly between two female fittings, very little of the nipple remains exposed. A close nipple can only be unscrewed by gripping one threaded end with a pipe wrench which will damage the threads and necessitate replacing the nipple, or by using a specialty tool known as a nipple wrench (or known as an internal pipe wrench) which grips the inside of the pipe, leaving the threads undamaged. When the ends are of two different sizes it is called a reducer or unequal nipple.

-

Pipe Nipple Dimension Standard

Threads used on nipples are BSP, BSPT, NPT, NPSM, and Metric.

The pipe nipple has different dimension standards according to different thread manufacturing standards. And the threads have different types. The most commonly used types are NPT threads and BSP Threads. NPT is an American standard tapered thread, while BSP is a British standard thread. BSP thread has tapered type BSPT and parallel type BSPP.

Pipe Nipple Materials are carbon steel or stainless steel

Pipe Nipple Structure is welded or seamless

Pipe Nipple Finish is galvanized or black

Pipe Nipple Types are TOE pipe nipple/welding nipple, TBE pipe nipple/barrel nipple, close nipple/running nipple, shoulder nipple, etc.

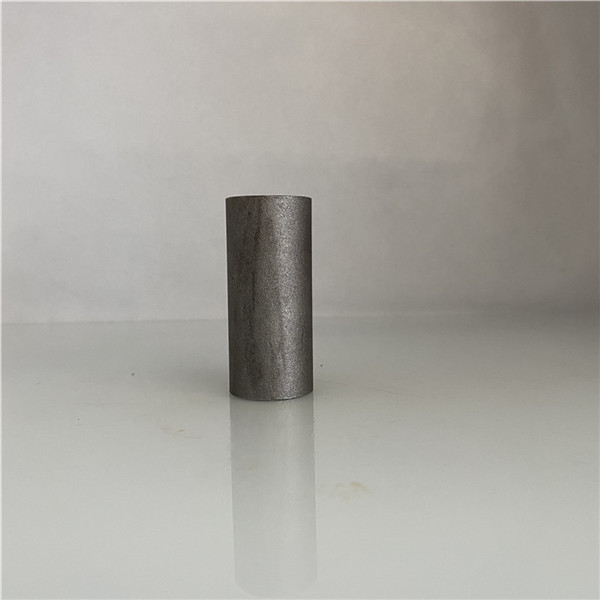

2. What Is A Pipe Coupling?

A coupling is a short tube, also called an outer joint; it is a commonly used accessory for industrial pipe connections. The forged coupling is formed by heating and forging with a steel ingot or a round bar and then machined on the lathe to make the thread. The main manufacturing standards are ASTM A865, ASME B1.20.1, etc.

According to the connection type, the coupling can be divided into socket coupling and threaded coupling generally. Specifically, it can be divided into single-socket coupling, double-socket coupling, single-thread coupling, and double-threaded coupling. The socket coupling adopts the socket structure to reduce the cost and is extremely convenient to install, use, and maintain, meanwhile, it embodies excellent anti-leakage performance. Thanks to its user-friendliness, it is widely used in civil construction, industry, agriculture, and other fields.

-

What is the threaded pipe coupling?

A threaded pipe coupling (or a coupler) (used in piping or plumbing) is a very short length of pipe or tube, with female threads at both ends that allow two pipes or tubes of equal or different sizes to be joined together. Pipe couplings are pipe fittings that help to extend or terminate pipe runs. These pipe fittings are also used to change pipe size. It's also used to repair a broken or leaking pipe.

There are so many different types of couplings available and each one has its specific application. For example, when connecting drop pipes in a well, you may consider using merchant couplings to connect them.

Pipe Coupling Materials are carbon steel or stainless steel

Pipe Couplings Structure is seamless

Pipe Couplings Finish is galvanized or black

Pipe Couplings Types are merchant full coupling, merchant half coupling, API Line pipe coupling, etc.

3. The Difference Between Pipe Nipple And Pipe Coupling Are As Follows:

In summary and can also be seen from the above pictures that the thread of the steel pipe nipple is male, that is the external thread; the thread of the steel pipe coupling is female, that is the internal thread. That is to say, the two pipes or fittings directly connected with the steel pipe nipple are sheathed and fastened outside, while the two pipes or fittings directly connected with the steel pipe coupling are tightened into the inside.

We are one of the excellent pipe fitting manufacturers and exporters in China. We supply all kinds of threaded pipe fittings at factory prices. If you have any questions, please click here to learn more about our products.

4. Can the two be used interchangeably?

Generally, pipe nipple and pipe coupling cannot used interchangeably for the following reasons:

-

Structural differences

Pipe nipples have external threads on both ends, while pipe couplings have internal threads on both ends, making their functions completely different. In connection design, these two types of fittings have different roles and cannot directly replace each other.

-

Functional purposes

The pipe nipple connects two fittings or pipes with internal threads, providing a linear extension function. The pipe coupling connects or extends the pipeline to two smooth-ended pipes.

-

Scenarios of mixed-use

In certain particular cases, pipe nipple and pipe coupling can be used together, for example:

If a smooth-ended pipe needs to be connected to a fitting with internal threads in the system, coupling and nipple may be required. Pipe nipples can work with Pipe Coupling to form complex piping joint configurations, but careful design ensures connection reliability.