Threaded End

The threaded end is the end of pipes that have male threads or female threads manufactured by mechanical processing, enabling pipes to be directly connected with pipe fittings through the threaded end. The threaded end is gradually tightened to achieve a seal and lock on the connection. The thread connection is fast and is commonly used in America, the Middle East, Southeast Asia, and other countries.

Types of Threaded Ends

Male Thread

Threads are processed on the outside.

The male threaded pipe is used with female pipe fittings or valves.

Female Thread

Threads are processed on the inside.

The female pipe thread is suitable for connecting with a male pipe connector.

Thread Standards

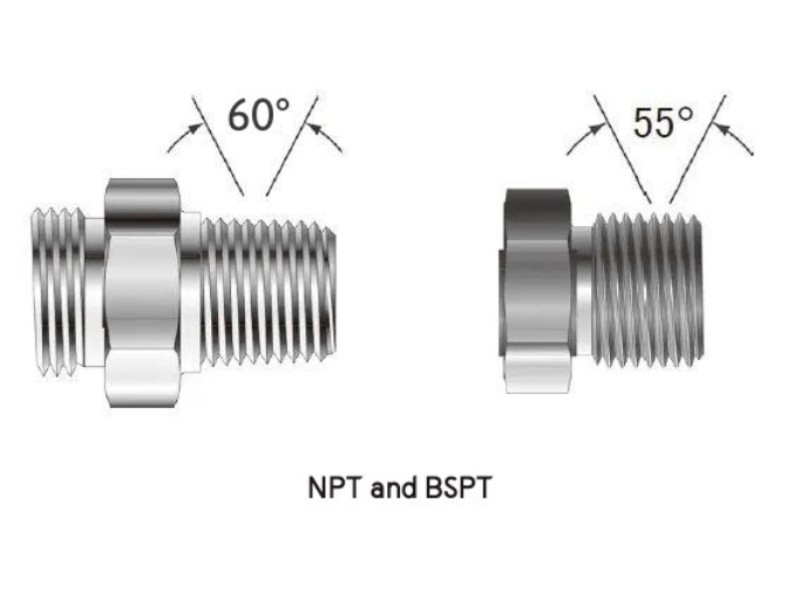

NPT (American Taper Pipe Thread): ANSI/ASME B1.20.1

Taper: 1:16, sealing achieved by extrusion, mostly used in industrial pipelines.

BSPT (Imperial taper Pipe Thread): BS 21 / ISO 7-1

Conical shape, tight, common in Europe/the Middle East.

BSPP (Imperial Parallel Thread): ISO 228

It needs to be sealed with a sealing ring or gasket.

Advantages of Threaded Ends

Installation without welding;

Reliable sealing, especially NPT and BSPT tapered thread;

It can be installed and removed repeatedly for examination and maintenance.

Highly cost-effective.

Plain End Pipe

Plain end is a smooth end without threaded, grooved, or flanged treatment. Typically, the end face is cut, deburred, and chamfered or beveled as necessary to facilitate welding, fitting, or direct insertion into the pipe fitting.

Advantages of Plain End

Simple construction and lower process cost;

It is easy to carry out bevel welding or joint customization according to the on-site process in the future.

Strong compatibility, convenient for stock management.

Limits

The plain end needed additional processing, which increased installation time and resources.

Plain end pipe requires additional fittings for fast installation or high-pressure sealing in piping systems.

Grooved End

The grooved end is a pipe end processing form widely used in fast installation piping systems, and its characteristic is that a standardized annular groove is formed at the end of the pipe through mechanical rolling grooving or cutting. This groove is used in conjunction with a grooved coupling, allowing for a rapid and reliable pipeline connection through the clamping of the rubber sealing ring and the metal housing.

Advantages of Grooved End

Fast installation

No welding, safety, smokeless, suitable for indoor or fire-free environments.

Displacement is allowed, making it suitable for systems that experience thermal expansion and contraction, as well as vibration.

Easy to maintain, fast removal, and replacement.

Suitable for large-scale installation.

High compatibility

Limitations of Grooved End

The supporting standard grooved coupling is required.

The tank size must be strictly controlled to prevent leakage or detachment.

Not suitable for extremely high-pressure working conditions (selection should be based on the coupling level).

There are requirements for the ellipticity and end roundness of the pipe material (especially for grooving processing).