What Exactly is a Hydraulic Fitting?

At its core, a hydraulic fitting is a connector used to join parts of a hydraulic system. These include hose pipes, tubes, pumps, valves, and cylinders. Unlike standard plumbing fittings, hydraulic fittings are specifically designed to endure extremely high pressures, often reaching hundreds or even thousands of PSI (pounds per square inch). Their primary function is to create a secure, leak-proof seal that can endure the dynamic forces and pressures inherent in hydraulic power transmission.

Why So Many Types Exist?

It's driven by the diverse requirements of hydraulic applications worldwide. Factors influencing the design and selection of fittings include:

-

Pressure Ratings: Different systems operate at vastly different pressures, requiring fittings rated accordingly.

-

Fluid Types: Compatibility with various hydraulic fluids (oil, water-glycol, etc.) is crucial.

-

Temperature Ranges: Fittings must perform reliably in extreme hot or cold environments.

-

Environmental Conditions: Exposure to corrosion, vibration, abrasion, and other external factors dictates material and design choices.

-

Connection Points: Different components have varying port configurations.

-

Tubing/Hose Types: Fittings must match the specific type and size of hose or rigid tubing being used.

-

International Standards: Different regions have developed their standards for threads and sealing methods over time.

Exploring Common Hydraulic Fitting Types

While the variations are numerous, fittings can generally be categorized based on their function or the type of connection they facilitate. Here are some common types you'll encounter:

Pipe Adapters

The pipe adapter changes the type, size, or gender of a connection on a port or line. They are incredibly versatile and often used to connect components with different thread standards or sizes, or to change a male connection to female, or vice versa.

Hoses

These fittings connect flexible hydraulic hoses to a port or another hose. They can be permanently attached or semi-permanently attached. Common ways to attach them include crimping for a permanent connection or using screws for a reusable connection. The end of a hose fitting will feature a specific thread or sealing surface (like JIC, ORFS, NPT, etc.) to connect to the system.

Tube Fittings

Tube fittings are used to connect rigid hydraulic tubing. They typically create a seal by mechanically deforming the tube or using a ferrule (a ring) to bite into the tube's surface, creating a strong, leak-free joint capable of handling high pressure. Examples include flare fittings (like JIC) and compression fittings.

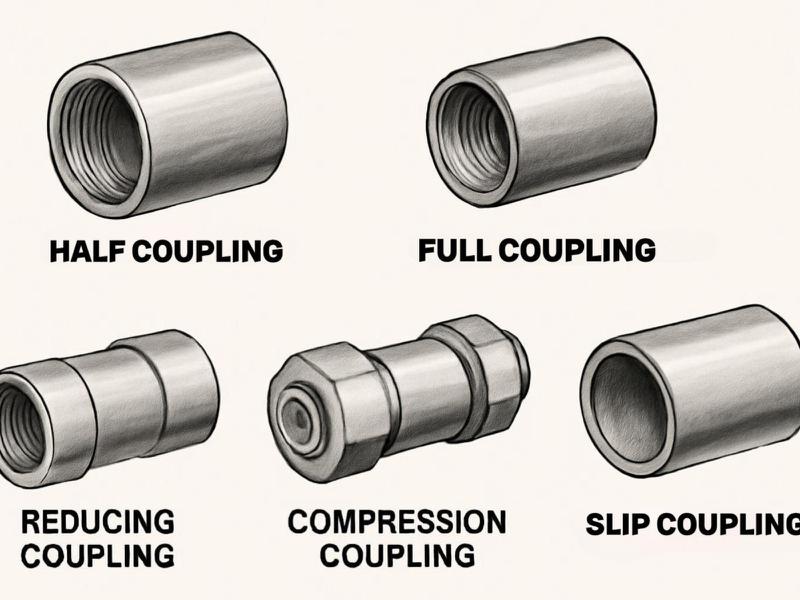

Couplings

Pipe couplings let you easily attach and detach hydraulic lines without using tools. They reduce fluid loss, which makes them very helpful when parts need to be changed or disconnected often.

Flange Fittings

Flange fittings are used mainly in high-pressure and large-bore applications. They have a flanged head that is bolted onto a port or surface. A seal, typically an O-ring, is seated in a groove on the flange face to prevent leaks. They are robust and provide a very secure connection.

Understanding Hydraulic Thread Types and Sealing Methods

One of the most critical aspects of hydraulic fittings is the thread type and the method used to create a seal. Incompatible threads or improper sealing can lead to dangerous leaks and system failure. Here are some of the most common standards:

NPT/NPTF (National Pipe Thread / National Pipe Taper Fuel)

Common in North America. These are tapered threads that create a seal by pressing together. The threads fit tightly, causing metal to contact metal. Sealant Tape (PTFE tape) or pipe dope is typically required for NPT. NPTF is a variation designed for a dryseal (no sealant needed) but requires precise manufacturing and assembly.

JIC (Joint Industry Council) 37° Flare

This is a common standard, especially in North America. JIC fittings use a 37° cone on the male fitting that seals against a 37° flared seat on the female fitting or adapter. This metal-to-metal seal is reliable and easy to assemble/disassemble.

ORFS (O-Ring Face Seal)

These fittings feature a flat face on the male end where an O-ring is seated. This O-ring seals against a flat face on the female swivel nut fitting. ORFS fittings offer excellent leak resistance, even under high pressure and vibration, and are easy to tighten.

BSP (British Standard Pipe) - BSPP & BSPT

BSPP (Parallel): Features a parallel thread and typically seals using an O-ring, washer, or bonded seal compressed between the faces of the male and female fittings.

BSPT (Tapered): This is a tapered thread, similar to NPT, that seals on the threads themselves and usually needs a sealant.

SAE O-Ring Boss (ORB)

Common in North America. This fitting has a parallel thread and seals via an O-ring compressed into a chamfered area (the "boss") on the female port or fitting. Provides a very reliable seal.

Metric Threads (e.g., DIN, ISO)

Used widely in Europe and Asia, metric fittings come in various standards (like DIN and ISO) and sealing methods (e.g., 24° cone, O-ring seals). Compatibility requires matching the specific metric standard and sealing configuration.

Common Materials for Hydraulic Fittings

The material of a hydraulic fitting impacts its pressure rating, corrosion resistance, and cost.

Carbon Steel

The most common material is due to its strength, durability, and cost-effectiveness. Carbon steel fittings are typically plated (zinc, chrome, or other coatings) to prevent rust and corrosion. Suitable for a wide range of general hydraulic applications.

Stainless Steel

Offers superior corrosion resistance compared to plated carbon steel, making it ideal for harsh environments such as marine, chemical processing, or food and beverage industries. Stainless steel fittings are more expensive but provide long-term reliability in demanding conditions.

Brass

Often used in lower-pressure hydraulic or pneumatic applications, as well as plumbing. Brass offers good corrosion resistance, is easy to machine, and is non-sparking, making it suitable for certain environments. It is generally not used for high-pressure hydraulic systems.

Choosing the Right Hydraulic Fitting

For buyers, guiding the correct fitting is crucial. The selection process involves considering several factors

-

System Pressure: The fitting's working pressure must meet or exceed the system's maximum operating pressure.

-

Fluid Compatibility: Check that the fitting and seal materials are compatible with the hydraulic fluid.

-

Temperature: The fitting must withstand the operating temperature range.

-

Environment: Consider external factors like corrosion, vibration, and abrasion.

-

Port Type and Size: Check the type and size of the port you are connecting to (for example, 1/2" NPT or -8 JIC).

-

Hose or Tube Size: Match the fitting to the specific size and type of hose or tube.

-

Application Standards: Some industries or applications require specific fitting types or materials.

Misidentification is a common and costly mistake. Using the wrong fitting can lead to leaks, system damage, and safety hazards.

Why Quality Fittings Matter for Wholesale Buyers?

Supplying high-quality hydraulic fittings is paramount for building a reputable company. Inferior fittings can lead to:

-

Frequent leaks and system downtime for customers.

-

Safety risks due to pressure failures.

-

Increased maintenance costs and customer dissatisfaction.

-

Damage to expensive hydraulic components.

Partnering with a reliable manufacturer and stocking quality fittings ensures that your customers receive products that perform reliably under pressure, leading to repeat business and a strong reputation.

Conclusion

It's important to know about different types of hydraulic fittings, including their thread standards, materials, and uses, if you work with hydraulic systems. This information is essential for buyers looking to source products for various uses. The variety exists to meet the specific demands of countless applications worldwide. By paying close attention to pressure, fluid, environment, and connection specifications, you can ensure the selection of fittings that provide safe, reliable, and leak-free performance.