If you’ve ever worked with pipes in plumbing, construction, or industrial systems, you know how crucial couplings are. They connect pipes, redirect flow, and even help with repairs. But how many types of pipe couplings are there? And which one should you use for your project?

Let’s break it down in simple terms to pick the right one without the headache.

What is Coupling?

Okay, let's talk about those handy little connectors that keep your pipes together – pipe couplings! Think of them as the handshake method between two pieces of pipe, making sure whatever's flowing inside stays put and goes where it needs to go. Choosing the right one is key, and there are a few different coupling types, each with its superpower.

Application of Coupling

Here are the key applications of pipe couplings:

Joining Pipes: Their primary job is connecting two pipe sections.

Pipe Repair: Used to fix damaged or leaking parts of a pipeline.

System Assembly: Essential for putting together new piping systems or adding to existing ones.

Connecting Different Pipes: Can join pipes of different sizes or materials.

Allowing Movement: Some types help handle vibration, expansion, or contraction.

Faster Installation: Often quicker and easier to install than welding.

Safer Installation: Can avoid the need for hot work like welding.

Temporary Setups: Great for quick or temporary connections.

Types of Couplings

Full Coupling and Half Coupling are like siblings in the threaded coupling family, often used for similar jobs (especially creating connections), but built slightly differently for specific purposes.

Full Coupling vs. Half Coupling: What's the Difference?

Full and half couplings are short pipes used to join things, but their structure gives them different primary roles.

- Full Coupling: The Two-Sided Connector

What it is: A short cylinder that's threaded on the inside at both ends.

How it works: Its basic job is to connect two pieces of threaded pipe in a straight line. You screw one pipe into one end and the other pipe into the other end. You can also weld the outside of a full coupling onto the surface of a larger pipe or tank. (though this is less common when welded onto a surface).

- Half Coupling: The Single-Sided Specialist

What it is: This is a short cylinder with a female thread on one end. The other end is typically plain or beveled, specifically designed to be welded onto a flat or curved surface.

How it works: Its main purpose is to be welded onto the side of a larger pipe. You weld the unthreaded end onto the surface. The threaded end gives you one convenient threaded connection to another pipe.

It cannot connect two pipes inline using threaded connections, because it only has threading on one end.

What if you need to connect a big pipe to a smaller one? A standard coupling won't cut it. Enter the reducing coupling! This one looks like a cone, allowing it to connect pipes of different diameters. It smoothly transitions the flow from different diameter pipes.

- Compression Coupling

They typically consist of a main part, a nut on each end, and a ferrule between the nut and the pipe. As you tighten the nuts, the ferrule gets compressed onto the pipe surface, creating a super-tight, leak-proof seal without needing threads or welding.

Ideal for situations where you need a joint that is easy to assemble and disassemble. Often used with copper, plastic, or even some metal pipes.

A slip coupling (sometimes called a repair coupling) doesn't have that stop. You can slide one end of the pipe onto the fitting, then line up the other end of the pipe, and slide the coupling back over both ends to bridge the gap. Super handy for repairs!

Your go-to for fixing a broken pipe section.

- Grooved Coupling

Grooved couplings are popular for larger pipes. These require the pipe ends to have a groove rolled or cut into them. A coupling is a part that fits over a gasket. The gasket seals against the pipe and fits into the grooves. Bolts hold the two halves of the housing together, keeping the pipes and gasket in place. They resemble a clamp.

Fast installation compared to welding allows for some flexibility and movement in the pipe system, and is easy to disassemble for maintenance.

Flange couplings are the answer when you need a robust connection, especially for large pipes, high pressures, or connections that might need to take things apart (like connecting a pipe to a pump or valve). This method involves attaching a "flange" (a flat, often round disk with bolt holes) to the end of each pipe. A gasket is placed between the two flanges. Use bolts to clamp the items tightly together. This creates a strong, leak-proof joint.

Very strong, reliable for high pressure/temperature, and makes it easy to connect/disconnect sections or equipment. Takes more space and effort than some other types.

Which Coupling Should You Use?

Here’s a quick comparison table to help you decide:

| Type | Best For | Advantages | Disadvantages |

| Full Coupling | Permanent connections | Strong, reliable | Requires welding/threading |

| Half Coupling | Tank/vessel connections | Simple installation | Limited to low-pressure uses |

| Reducing | Different pipe sizes | Versatile | May cause flow restriction |

| Compression | Quick repairs | No welding needed | Not ideal for high pressure |

| Slip Coupling | Emergency fixes | Easy to install | Less secure long-term |

| Flanged | High-pressure systems | Extremely durable | Heavy, requires bolts |

| Grooved | Fire sprinklers, HVAC | Fast installation | Needs special tools |

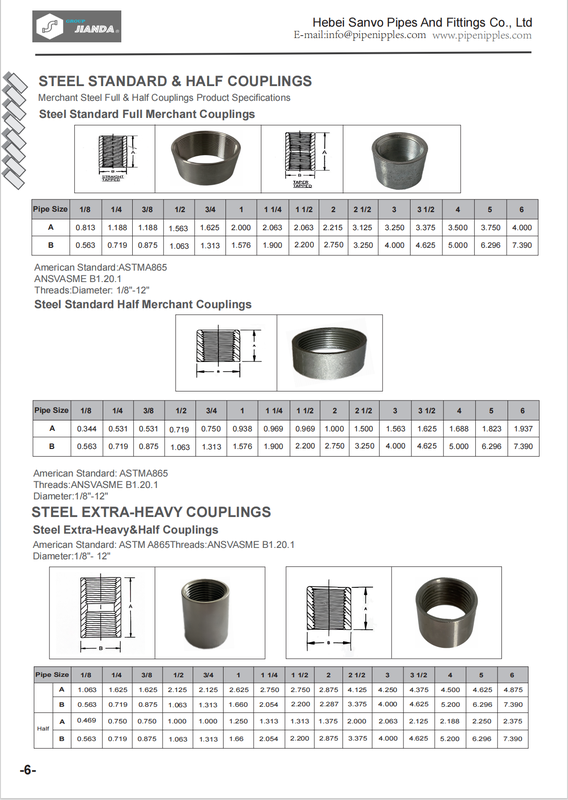

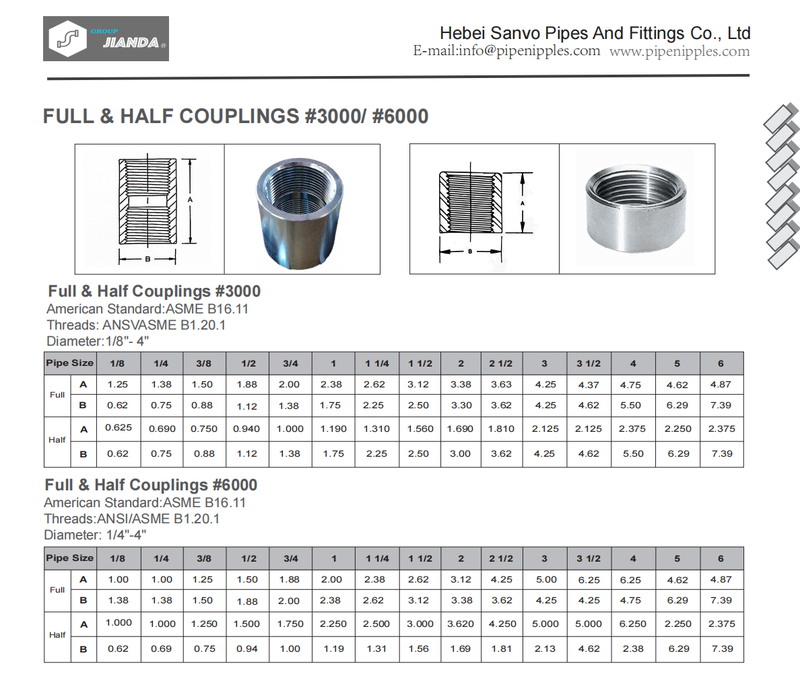

Coupling Dimensions