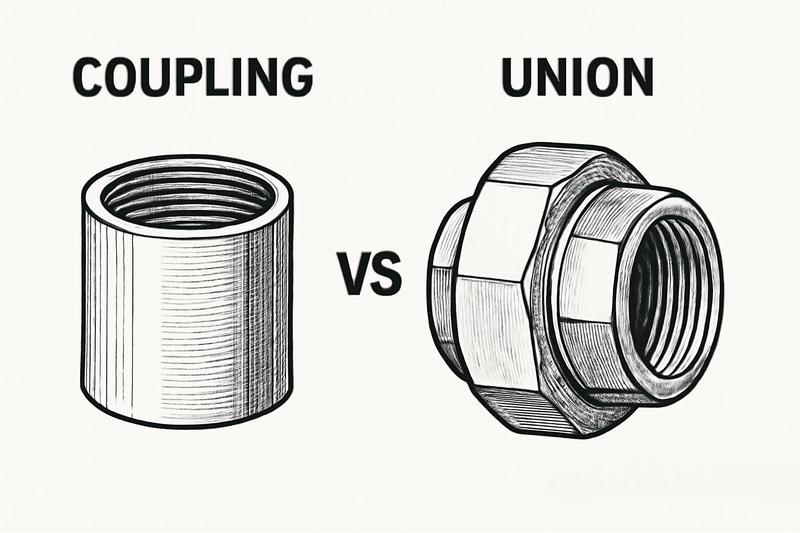

Both couplings and unions are used to connect pipes, while a plumbing union fitting (also called a pipe union fitting) is designed for easy maintenance and replacement.

A coupling is a short pipe that extends the pipeline and connects two pipes by welding or threaded connections. Pipe couplings provide a strong, permanent connection, while unions allow easy disassembly for maintenance.

While a union is for joining and disassembling components of a piping system, it is easy to connect two pipes or components, and to take them apart whenever needed for maintenance or replacement. It’s a reusable connection with a threaded middle section.

So, which one should you use?

Use a coupling when you need a permanent, fixed connection that won’t be disassembled.

Choose a union when future disassembly or maintenance is required, such as replacing parts or accessing other pipeline sections.

The choice depends on the material, pressure rating, and whether you’ll need to replace it later.

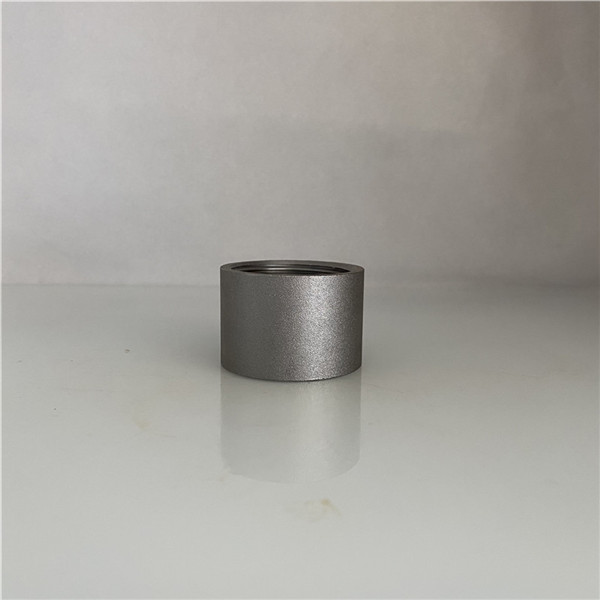

1. What is A Pipe Coupling?

A pipe coupling, also known as a pipe coupler, is a short piece of pipe used to connect two steel pipes through a threaded connection. The seal at the connection is threaded. Pipe couplings are mainly used to extend pipelines when a single pipe is not long enough. We provide couplings ranging from 1/8 inch to 12 inches and can customize them according to customer requirements.

Couplings are designed for strength and permanence, making them ideal for runs of pipe that aren't expected to be frequently altered.

-

Materials

Galvanized carbon steel, stainless steel, black carbon steel, PVC, and CPVC, among others.

-

Connection methods

Threaded connections, welding, sockets, and other related components are essential in various mechanical and structural applications. Threaded connections are common, especially for smaller diameters. Welding provides a strong, permanent joint. Sockets are used with socket-weld fittings.

-

Manufacturing standards

ASME B1.20.1, DIN2986, BS10241.

-

Manufacturing process

Forged pipe and couplings provide higher strength for high-pressure applications, while cast couplings are more cost-effective.

-

Application

Pipe couplings are convenient in civil construction, industry, agriculture, and other fields.

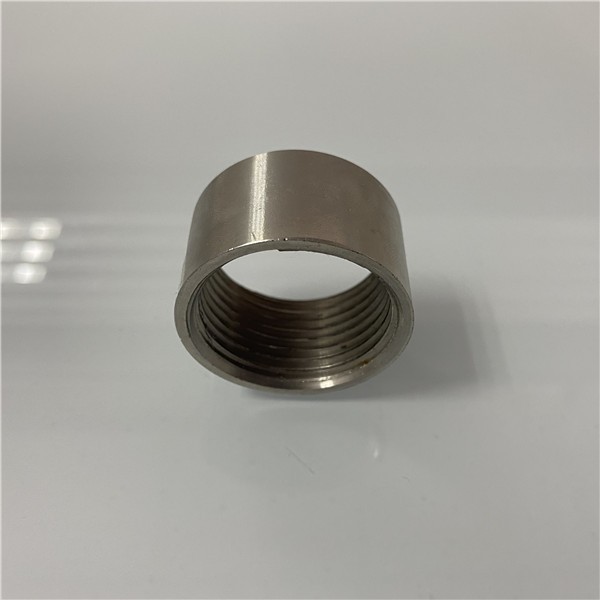

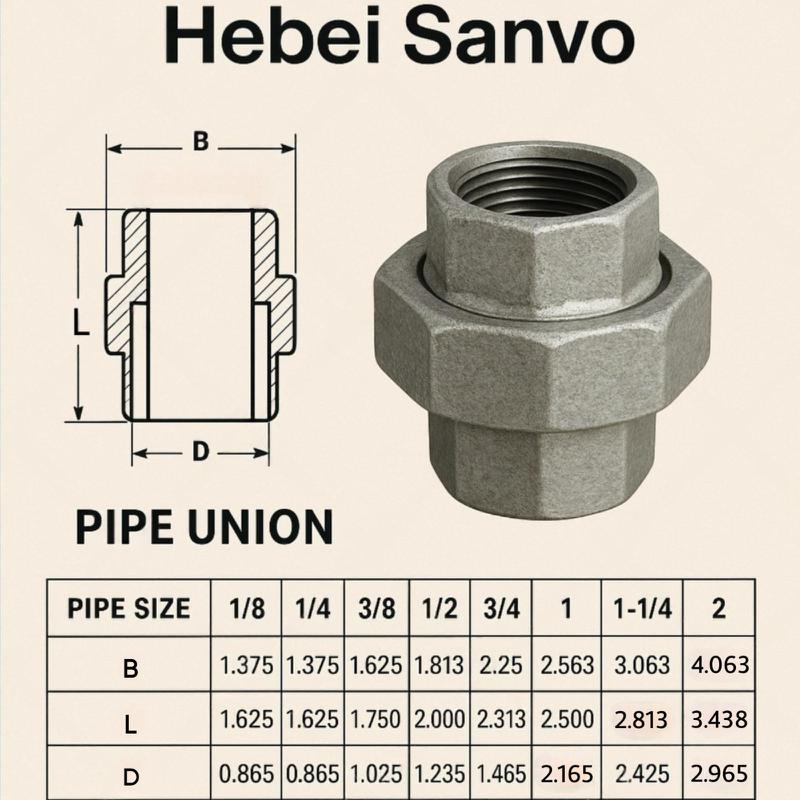

2. What Is A Pipe Union?

A pipe union fitting (also called a threads union) is a commonly used pipe connector that stands out because it can be easily installed and disassembled without rotating the pipes themselves. It mainly consists of three parts: the nut, the cloud head, and the flat connection. The pipe union is used at the ends of valves, water meters, and other pipelines.

A pipe union serves as a convenient disconnect point for maintenance. It's a versatile pipe union fitting.

-

Material

Threaded unions are in industries that require metals with high-pressure resistance. Materials such as carbon steel, stainless steel, alloy steel, and brass are commonly used, along with plastics like PVC, PE, and others.

-

Connection forms

Socket welding and threaded connection. (Socket welding is to insert a steel pipe into a socket for welding. Therefore, it is called a "socket "Or swivel joint"; the threaded connection is to screw the steel pipe into the screw hole for connection. Therefore, it is called a "threaded union". The threaded form is particularly popular for its ease of use in many applications.

-

Manufacturing standards

ASME B16.11, MSS SP 83.

-

Definition

Threaded union refers to a pipe connection with a thread, the most common type of pipe fitting in industry and life. The threaded union simplifies pipeline connections, allowing for easier and more cost-effective disassembly and replacement.

-

Type

There are equal diameters and different diameters of threaded unions.

Deep Dive: Threaded Union Essentials for Piping Systems

A threaded union is the most versatile type of pipe union, combining quick assembly with reliable sealing. Its threaded design allows direct screw-in connections without welding – ideal for maintenance-prone systems.

Key Features of Threaded Pipe Unions and Plumbing Union Fittings

-

Modular Design

-

Consists of three reusable components: female threaded union ends (with internal threads), a central nut, and a sealing surface.

-

Enables disassembly by loosening the nut while keeping pipes stationary (critical for cramped spaces).

-

-

Standardized Threaded Union Dimensions

-

Follows ASME B16.11 for pressure ratings (Class 2000 to 6000) and ANSI B1.20.1 for thread specs (NPT/BSPP).

-

Common sizes: 1/8" to 4" for industrial use; 1/2" and 3/4" dominate plumbing applications.

-

-

Connection Types: Both ends have internal threads to connect male-threaded pipes.

Applications of Threaded Pipe Unions

| Scenario | Recommended Fitting |

|---|---|

| High-pressure steam lines | Forged steel threaded pipe union fitting with graphite gasket |

| Water treatment systems | Brass/PVC threaded union joint (corrosion-resistant) |

| Hydraulic maintenance points | Stainless steel union with O-ring seal |

For chemical pipelines, use stainless steel threaded unions; for potable water, brass unions are recommended.

3. Pipe Coupling VS Union

Both pipe couplings and pipe unions are pipe fittings.

The fundamental difference between a coupling and a union lies in their functions: a coupling connects pipe to pipe or pipe to a swedge, while a union joins and disassembles components of a piping system, such as a steam trap or control valve, for maintenance or replacement. The use of couplings or unions is not a code issue.

Use couplings to extend pipelines; use unions for components that require frequent maintenance, such as valves and radiators. For larger diameters, flanges are preferred.

The pipe coupling has threaded coupling, butt welded coupling, and socket coupling, while the pipe union only has threaded union and socket union. Unlike couplings, pipe unions allow easy disconnection without the need to rotate the pipes.

From a practical application point of view, the union is used on low-pressure occasions, while pipe coupling is suitable for high-pressure occasions. The union is a threaded connection generally used in public engineering placements of less than 10kg.

4. Advantages and Disadvantages

Pipe couplings are durable, leak-resistant connections for high-pressure systems, but are difficult to disassemble.

Unions disassemble easily, making maintenance and part replacement easy. The connection method can be selected based on your needs, providing greater flexibility. However, it is less robust when subjected to high pressure or strong vibrations than some fixed connection types. With repeated disassemblies over time, it is likely to become worn and less efficient, making it crucial to handle it with care to maintain its performance.

| Plumbing Connector | Advanatges | Disadvantages |

| Coupling | Simple, compact, strong, cheaper | Not conducive to disassembly at any time |

| Union | Easy to disconnect and reconnect, ideal for repairs | Bulkier, a bit more expensive |

5. Industry Applications: Where Are They Used?

Both pipe couplings and pipe unions are ubiquitous in various industries, but their specific placement differs

- Pipe Couplings are found throughout extensive pipeline networks in:

-

Oil and Gas transmission and processing

-

Chemical and Petrochemical plants

-

Water supply and distribution mains

-

Large-scale HVAC systems

-

Structural applications (e.g., handrails)

- Pipe Unions are strategically placed in systems requiring maintenance access, such as:

-

Near pumps, boilers, chillers, and other mechanical equipment

-

Upstream and downstream of control valves, isolation valves, and check valves

-

Around filters, strainers, and meters

-

In HVAC systems, near coils and other components requiring cleaning or replacement

-

In residential and commercial plumbing near water heaters, meters, and fixtures

Understanding these typical placements helps wholesalers anticipate customer needs based on the type of project they are undertaking.

6. Standards and Compliance

Adherence to manufacturing standards is non-negotiable for buyers focused on quality and reliability. Fittings manufactured to standards like ASME B16.11 or MSS SP-83 ensure consistent quality, dimensional accuracy, and specified pressure/temperature ratings. Sourcing from manufacturers who comply with these standards guarantees that the fittings will perform as expected and be compatible with other system components, reducing risks in large-scale installations.

7. Conclusion

Consider the coupling if you require a simple, strong, and permanent way to extend a pipe. If you need a connection point that allows for quick and easy removal of a component for service, a union is your best friend.

Choose pipe couplings for permanent pipeline extensions and unions for easy maintenance. For bulk orders of threaded steel fittings, contact Hebei Sanvo for high-quality, standard-compliant products.

8. About us

Hebei Sanvo supplies high-quality threaded steel fittings, including carbon steel and stainless steel couplings and unions. Contact us for bulk orders and competitive prices.