What is Cast Fitting?

Cast Pipe Fittings are pipe fittings that are formed by melting metal and pouring it into a mold. It is a type of pipe fitting manufactured by the casting process and is suitable for a variety of fluid transfer systems.

Is Stainless Steel good for Casting?

Yes, stainless steel fittings can be cast, but whether they are “suitable” according to the use and performance requirements must be determined.

Stainless steel has good liquidity and corrosion resistance, and after the metal is melted, it can be precision-cast into a variety of complex shapes of fittings. There are indeed many stainless steel casting fittings in the industry. It is widely used in valves, flanges, tees, elbows, and other products.

-

The Advantages of Casting Stainless Steel Pipe Fittings

Flexible molding: Complex structures or large-sized pipe fittings can be manufactured.

Smooth surface: Precision casting brings a high-precision appearance.

Lower cost: Low and medium-pressure systems are cost-effective.

Excellent corrosion resistance: Retains the antioxidant and corrosion resistance properties of stainless steel materials.

-

Limitations and Shortcomings

Organization density is lower than forging; there may be pores, shrinkage, and other minor defects.

Mechanical properties are slightly worse: not as good as the pressure and impact resistance of forging.

Not suitable for high-pressure, high-temperature environments, such as petrochemical pipelines or boiler systems, forged stainless steel pipe fittings are not appropriate.

What Temperature can you Cast Stainless Steel?

Stainless steel has a melting point of approximately 1370°C to 1450°C; the actual pouring temperature is usually about 50 to 150°C above the melting point because it needs to keep the metal completely molten and fluid during casting.

-

Casting Temperature Control Points

-

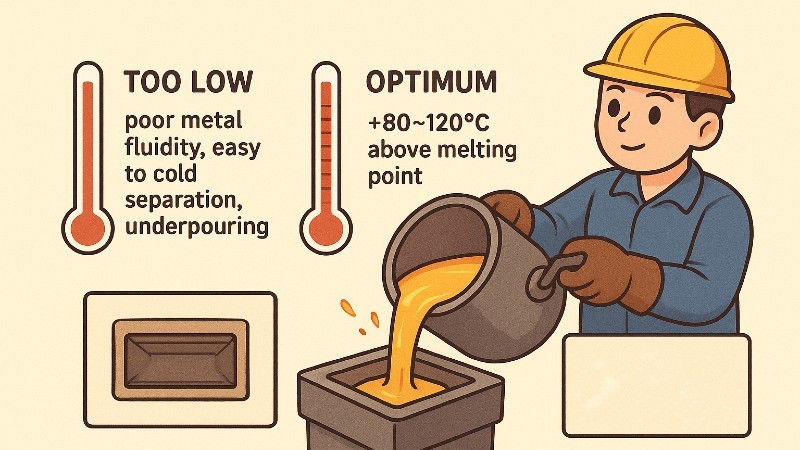

Too low a temperature → poor metal fluidity, easy to cold separation, underpouring;

-

Too high a temperature → easy to lead to coarse grains, serious oxidation, increased porosity;

-

The optimum temperature zone is commonly controlled at +80~120℃ after the metal is completely melted, fine-tuned according to the mold material and casting thickness.

What is better, Cast or forged?

Cast fittings have a lower cost and are more suitable for low- to medium-pressure and general liquid transportation systems. Please select cast fittings for projects that require low cost, low pressure, or complex structures, such as water supply and drainage; food processing, and low-pressure mechanical pipelines.

Forged fittings are superior for high-pressure, high-temperature, and critical systems, but are a little expensive than cast fittings. Please use the forged fitting when a project involves high pressure, high temperatures, or critical systems, such as oil and gas pipelines, boilers, and high-pressure chemical systems.