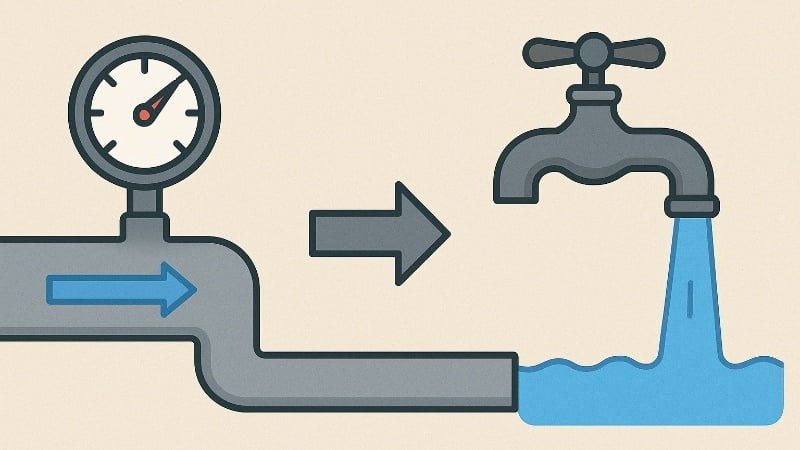

Relationship between Pressure and Flow Rate

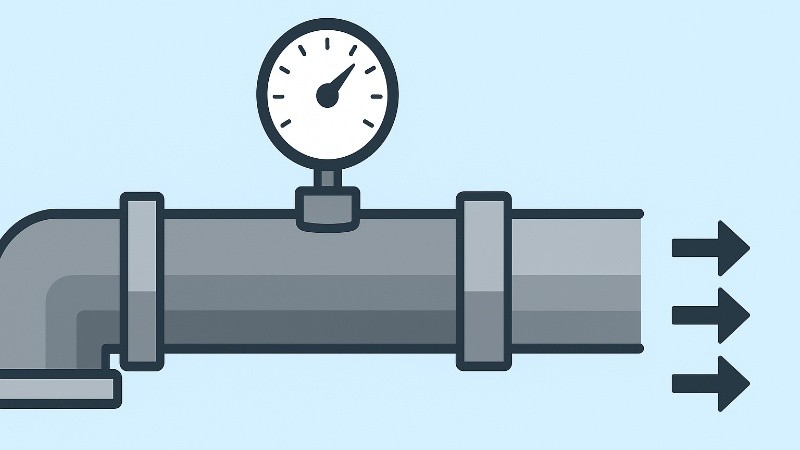

"Pressure" of a pipe refers to the internal pressure that the pipe can withstand or actually bears during use. This pressure results from forces exerted on the pipe wall by either flowing or stationary liquid or gas in the pipelines.

It can be understood as: the pressure exerted by the internal medium of the pipe pushing against the pipe wall.

"Flow" is the amount of fluid through the pipe in unit time.

Pressure difference greater, flow greater. It's like the larger the faucet is turned on, the greater the water flow.

Schedule 40/80/160 Pipe Pressure Rating Chart

| NPS | OD (in) | Wall | Pressure (psi) | ||||

|---|---|---|---|---|---|---|---|

| Sch 40 | Sch 80 | Sch 160 | Sch 40 | Sch 80 | Sch160 | ||

| 1/8 | 0.405 | 0.068 | 0.095 | 9,504 | 14,149 | ||

| 1/4 | 0.540 | 0.088 | 0.119 | 9,182 | 13,109 | ||

| 3/8 | 0.675 | 0.091 | 0.126 | 7,405 | 10,752 | ||

| 1/2 | 0.840 | 0.109 | 0.147 | 0.187 | 6,358 | 8,575 | 11,908 |

| 3/4 | 1.050 | 0.113 | 0.154 | 0.218 | 5,273 | 7,187 | 9,003 |

| 1 | 1.315 | 0.133 | 0.179 | 0.250 | 4,956 | 6,670 | 9,111 |

| 1¼ | 1.660 | 0.140 | 0.191 | 0.250 | 4,133 | 5,638 | 7,092 |

| 1½ | 1.900 | 0.145 | 0.200 | 0.281 | 3,739 | 5,158 | 7,357 |

| 2 | 2.375 | 0.154 | 0.218 | 0.344 | 3,177 | 4,498 | 8,027 |

| 2½ | 2.875 | 0.203 | 0.276 | 0.375 | 3,667 | 5,095 | 7,136 |

| 3 | 3.500 | 0.216 | 0.300 | 3,181 | 4,509 | ||

| 4 | 4.500 | 0.237 | 0.337 | 2,694 | 3,903 | ||

| 6 | 6.625 | 0.280 | 0.432 | 2,143 | 3,371 | ||

This table lists the pipe pressure rating of various Nominal Pipe Sizes under different pipe schedules (Sch 40, Sch 80, Sch 160).

Notes:

-

Pressure is the allowable working pressure, not the burst pressure.

-

Sch 160 is not available for all pipe sizes.

Flow Control Valve Types

Flow control valves are designed to regulate the rate of fluid flow within a pipeline system. Different valve types offer varying levels of control accuracy, operating mechanisms, and suitability for specific fluid characteristics and system pressures. Below are the most common types of flow control valves used in industrial and commercial piping systems.

-

Globe Valves

Globe valves are one of the most widely used flow-control valves.

They feature a linear motion design, where the disc moves up and down to create precise throttling.

-

Check Valve

These valves use actuators—whether pneumatic, electric, or hydraulic to control the valve opening based on a control signal.

-

Butterfly Valves

Butterfly valves use a rotating disc to regulate flow. When partially open, they provide moderate flow control, with advantages as low weight and cost.

-

Diaphragm Valves

A flexible diaphragm is pressed against a seat to control flow.

Ideal for corrosive or dirty fluids.

-

Needle Valves

Needle valves provide precise flow control because of their narrow, tapered plunger.

-

Gate Valve

Gate valves are designed for fully open or fully closed operation.

Frequent adjustments lead to wear on the sealing surfaces, shortening the service life. Not suitable for precise flow control.

-

Pinch Valve

Pinch valves offer variable control by compressing the hose to adjust the flow area from 0% to 100%. Their lined hose construction is effective for regulating slurries, particulate matter, and corrosive media.

Summary

| Valve Type | Flow Control Ability | Best For | Notes |

|---|---|---|---|

| Globe | Precise | General liquids, steam | Ideal control valve |

| Check | None | Backflow prevention | Cannot control flow |

| Butterfly | Moderate | Large pipes, water | Rough throttling |

| Diaphragm | Moderate | Corrosive, slurry | Smooth throttling |

| Needle | Very fine | Low flow, gas | Precision control |

| Gate | Not suitable | On/off service | Do not throttle |

| Pinch | Good | Slurry, particulates | Continuously adjustable |

Globe Valves, Needle Valves, and Pinch Valves can provide precise control for flows.

Butterfly valves and diaphragm valves are effective for controlling moderate flow piping systems.

When selecting the right valve to control flow, consider accurate needs, the type of fluid it will handle, as well as the pressure, temperature, and operating conditions of the piping system.

Can a Ball Valve Control Flow?

Yes, the ball valve can control flow, but it is not recommended for precise flow control.

Ball valves are designed for on/off isolation, not throttling.

Ball Valves Mainly Function

-

Rough flow control

-

Not suitable for precise control

-

Short-term throttling is possible, but long-term throttling will damage the valve.

When is a ball valve used for throttling?

-

The flow medium is clean

-

The control requirement is low

-

Valve is used temporarily, not continuously