Fire Sprinkler Pipe Material

Dear customer,

Carbon steel and CPVC pipes are the two most commonly used materials in sprinkler systems. Each material is suited for different project types, installation conditions, and budget levels. Below is a clear and practical guide to their benefits, budgets, and applications to help you buy the most suitable one for your project.

Carbon Steel Pipe

Carbon steel pipe is the most widely used fire protection piping globally, in virtually all commercial and industrial fire sprinkler systems.

Benefits of Choosing Carbon Steel Pipe

High strength, withstands 175–350 psi

Suitable for high flow rates and pressures

Comprehensive certification systems (UL/FM, etc.)

Lower cost

Carbon steel pipe is the default standard configuration for fire protection systems in medium to large commercial and industrial buildings.

CPVC Pipe

CPVC is an engineered plastic pipe specifically designed for fire sprinkler systems (must be UL/FM certified).

Advantages of CPVC

Lightweight (only 1/6 the weight of steel pipe)

Fast installation by solvent cement joints without welding or threading

Corrosion-resistant, scale-free

Smooth inner walls minimize head loss

Low total cost (material + labor)

CPVC Limitations

Not heat-resistant (unsuitable for boiler rooms, rooftop sun exposure)

Not suitable for industrial settings

Cannot handle high pressure

Cannot replace main trunk lines (only for branch lines)

CPVC piping is ideal for residential and light commercial systems, emphasizing low cost and rapid installation.

Carbon Steel vs. CPVC

| Factor | Carbon Steel | CPVC |

|---|---|---|

| Best for | Commercial & industrial | Residential & light commercial |

| Pressure | High (175–350 psi) | Moderate (≤175 psi) |

| System Types | Wet, dry, pre-action, deluge | Wet only |

| Durability | High strength; may need coating | Excellent corrosion resistance |

| Installation | Threading / Grooved / Welding | Solvent cement |

Surface Treatment and Applications of Fire Sprinkler Pipe

1. CPVC Fire Protection Piping

CPVC must utilize fire-rated materials compliant with UL/FM certification systems.

CPVC pipe is classified as a plastic material, not a metal.

Surface Treatment

CPVC piping requires minimal external surface treatment.

Reason: CPVC inherently resists corrosion and scaling, eliminating the need for metallic anti-corrosion processes.

Applicable Systems

Suitable for wet systems.

Not suitable for dry systems (prone to brittleness due to temperature fluctuations).

2. Carbon Steel Fire Piping

Common Material Standards

ASTM A53

ASTM A795

ASTM A135

Carbon steel fire sprinkler piping for UL/FM certification

Surface Treatment Methods

Carbon steel pipes have multiple choices for surface treatments for long-term corrosion protection in fire systems:

- Black Pipe

Natural steel surface with light rust-preventive oil coating

Suitable for: Wet systems + indoor environments

- Red Painted / Red Epoxy Coated Pipe

Surface coated with red fire-rated paint or epoxy powder coating

Paint thickness (typical range):

40–80 μm (microns) common

High-end epoxy powder up to 120–250 μm

Applications:

Indoor, wet systems

Ordinary corrosion environments

- Galvanized Pipe

Used in locations with high corrosion resistance requirements, such as:

Dry systems

Damp areas (e.g., basements, semi-outdoor)

Highly corrosive regions (coastal areas)

Galvanized thickness (per ASTM A123 / ASTM A153):

Common: 45–80 μm (550–1100 g/m²)

Some fire protection projects require ≥85 μm

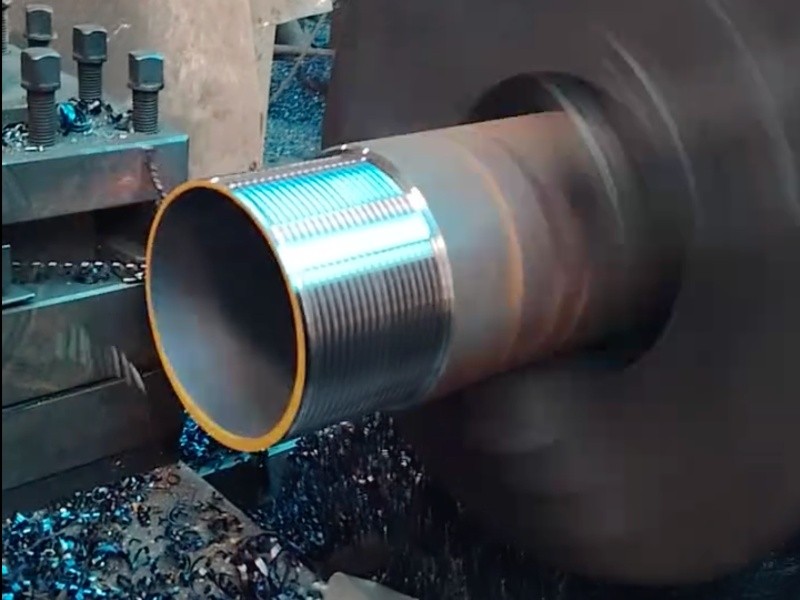

- Grooved / Threaded Pipes

Post-processing involves rust-proof paint application

Commonly used in rapid installation systems

Compatible with grooved fittings, valves, sprinklers

FAQ

Q: What is your monthly production capacity?

A: Our factory possesses large-scale production capacity, achieving a monthly output of 3,000–5,000 tons (including black pipes, galvanized pipes, and CPVC pipes). Production lines can be flexibly adjusted according to the order composition.

Q: What is the lead time for bulk production?

A: Standard specifications: 15–25 days

Custom specifications (special thicknesses, spray colors, etc.): 20–30 days

Q: What specifications are available in stock?

A: Our standard inventory includes:

1/8" – 4" (DN15–DN100) black & galvanized pipes, CPVC pipes

Schedule 10 / Schedule 40

Standard length: 6m - 72m

Q: Do you offer OEM painting, marking, and packaging?

A: Yes, we provide comprehensive OEM customization services:

Painting (red, black, gray, customer-specified colors)

Marking (brand name, specifications, standards, UL/FM information, etc.)

Packaging (stretch wrap, steel strapping, pallets, labels, etc.)