What is a threaded steel pipe?

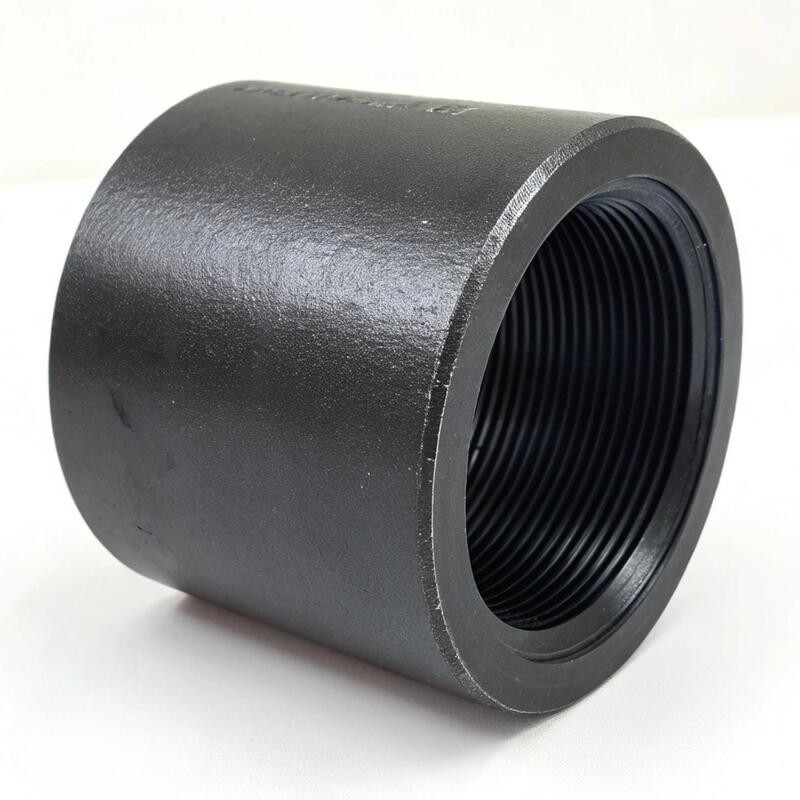

A threaded pipe, also known as a pre-cut pipe or ready-cut pipe, is a type of pipe that is prepared with threaded ends for easy connection. A threaded steel pipe is a finished pipe product with threads machined at one or both ends.

Characteristics of threaded steel pipes

1. Threads on both ends or one end

Common thread standards include:

NPT (American standard)

BSPT (British Standard)

2. The Advantage of Pre-cut Pipe

No welding required

Direct connection to threaded fittings like elbows, tees, couplings, pipe clamps, valves, etc.

Ideal for rapid installation and maintenance.

3. Common Materials

Carbon Steel: Black Steel (black surface finish), Hot-dip galvanized

Stainless Steel Threaded Pipe: 304, 304L, 316, and 316L

4. Primary Applications

Threaded steel pipes are commonly used in:

Civil & Engineering Water Supply

LPG / Natural Gas

Sprinklers

HVAC Systems, Compressed Air

Industrial Piping, Mechanical Equipment

Low- and Medium-Pressure Networks

Threaded Steel Pipe vs Plain-End Steel Pipe: Key Differences

1. Appearance

Threaded Steel Pipe:

Pipe is machined into threaded ends

Can be directly connected to a threaded fitting

Plain-End Steel Pipe:

Pipe ends feature plain ends or beveled ends

Cannot be directly connected to threaded fittings

2. Different Manufacturing Processes

Threaded Steel Pipe:

Requires an additional cut threading process

Threads are machined on a lathe/threading machine

Higher manufacturing precision requirements (taper, depth, accuracy)

Plain End Steel Pipe:

No end processing required

Directly used for welding, flange connections, etc.

3. Usage Method Differences

Threaded Pipe: Can be directly screwed into place without welding required, screw on threaded components like elbows, tees, pipe clamps, valves, etc.

Plain End Steel Pipe: Requires welding or flange connections

4. Cost

Threaded Steel Pipe is a little more expensive than plain-end pipe due to an additional manufacturing step.

Plain End Pipe has a lower raw material cost, resulting in a lower price.

Technical Specifications

| Specification | Details |

|---|---|

| Size Range | 1/2" – 6" (DN15 – DN150) |

| Wall Thickness | SCH10 / SCH40 / SCH80 |

| Standards | ASTM A53 / A106 / A135 / EN10255 / JIS |

| Thread Types | NPT / BSPT / BSPP |

| End Types | Threaded End |

| Surface Options | Black / Hot-dip galvanized |

| Material | Carbon Steel, Stainless Steel (304 / 316) |

Packaging & Delivery

Pipes bundled with steel straps

Protective plastic caps on both ends

Thread protectors to avoid damage during transit

Loaded on pallets for safe handling

Customized marking and labeling available

Compliance & Certifications

ISO 9001 certified manufacturing process

UL/FM approval available for fire protection applications

CE marking for European compliance

Mill Test Certificates (MTC / EN10204 3.1)

FAQs

Q1: What is the difference between NPT and BSPT threads?

A: NPT is the American standard tapered thread, while BSPT is the British standard tapered thread. Both provide tight seals but differ in angle and thread pitch.

Q2: Can threaded pipes be used in high-pressure systems?

A: Threaded steel pipes are suitable for medium-pressure systems. For very high-pressure applications, welded or flanged pipes are recommended.

Q3: Do you offer customized lengths?

A: Yes, we can cut pipes to customer-specified lengths.

Ordering Information

MOQ: Negotiable, both small trial orders and bulk orders are welcome.

Lead Time: 15–30 days, depending on quantity

Available Lengths: 18 to 72 inches, or customized

Custom Thread Options: NPT, BSPT, BSPP