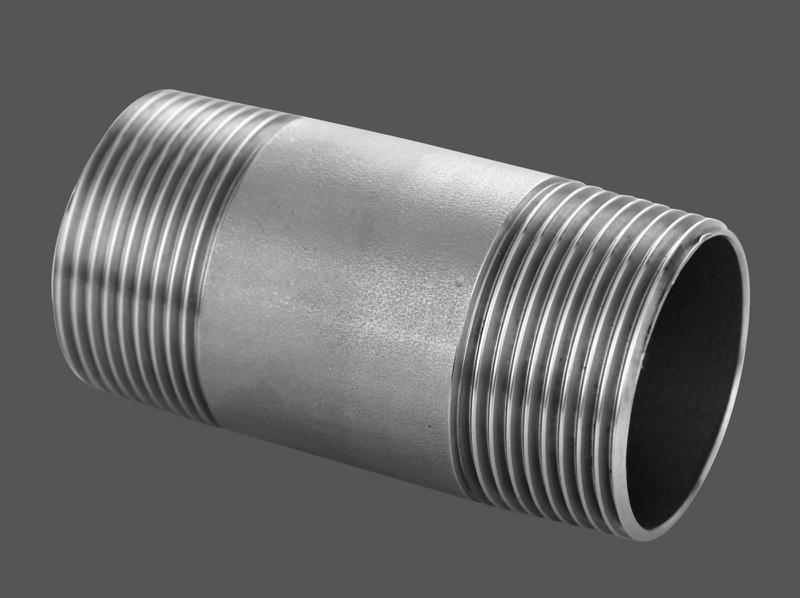

What is NPT Thread?

NPT thread (National Pipe Thread) is a U.S. standard tapered thread commonly used in industrial pipe fittings to ensure a tight, leak-resistant seal. With a 60° thread angle and tapered design, NPT fittings are ideal for high-pressure applications in water, gas, and oil systems. They are widely used in stainless steel, galvanized steel, and black steel piping. For international buyers, please note that NPT is not compatible with BSP threads without the use of adapters. Always confirm thread standards when sourcing pipe connectors for U.S.-spec systems.

Difference Between BSP and NPT

When sourcing pipe fittings for international projects, choosing between BSP (British Standard Pipe) and NPT (National Pipe Thread) is critical. Misalignment in thread standards can lead to leaks, downtime, and increased costs.

1. Thread Type

| Feature | NPT Thread | BSP Thread |

|---|---|---|

| Thread Type | Tapered | BSPT (tapered) or BSPP (parallel) |

| Seal Method | Thread interference + sealant | Mechanical seal (BSPP) or interference (BSPT) |

| Use of PTFE tape | Required | Depends on the BSP type |

NPT threads seal through the taper and require Teflon tape or thread sealant. BSP threads come in two types:

-

BSPT (tapered) – similar to NPT but with a different angle

-

BSPP (parallel) – requires a washer or O-ring to seal

2. Thread Angle & Pitch

-

NPT Thread Angle: 60 degrees

-

BSP Thread Angle: 55 degrees

-

Thread Pitch: Even if the pitch is similar, the different angle means they are not interchangeable.

This makes NPT and BSP fittings incompatible without the use of adapters.

3. Application & Material Compatibility

| Thread Type | Common Materials | Typical Applications |

|---|---|---|

| NPT | Stainless steel, galvanized, black steel | Plumbing, oil & gas, compressed air |

| BSP | Brass, stainless steel, plastic | Water systems, HVAC, and irrigation |

4. Can NPT and BSP Threads Be Used Together?

No. Although they appear similar, the thread angle and sealing method differ, which can result in leakage if forced together. Use thread adapters or match standards across your components.

Final Tip for Procurement:

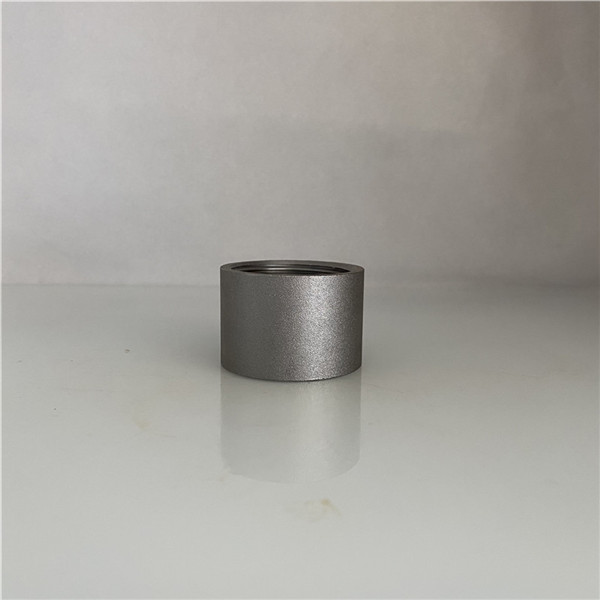

When sourcing pipe nipples, couplings, or unions, always double-check:

-

Thread standard (BSP vs NPT)

-

Material compatibility

-

Application pressure rating

Using the wrong thread type can cause system failure, waste your business time, and money.

Why use NPT Fittings?

NPT stands for National Pipe Thread, a U.S. standard for tapered pipe threads designed to create a pressure-tight seal in piping systems. Commonly used in industrial pipe fittings, NPT threads are engineered with a 60° thread angle and a taper that allows for a secure, leak-resistant connection, especially when used with sealants like PTFE tape.

Choosing NPT pipe fittings is essential when sourcing systems that operate under high pressure, such as water supply lines, compressed air systems, gas pipelines, or oil transfer setups. NPT fittings are especially popular in the U.S. market and widely available in stainless steel, galvanized steel, and black carbon steel.

For international buyers, it's essential to note that NPT threads are not compatible with BSP threads due to differences in angle and thread form, making it crucial to confirm thread standards during procurement. If you're sourcing pipe connectors for American or North American systems, NPT is the preferred standard for long-term reliability and compatibility.