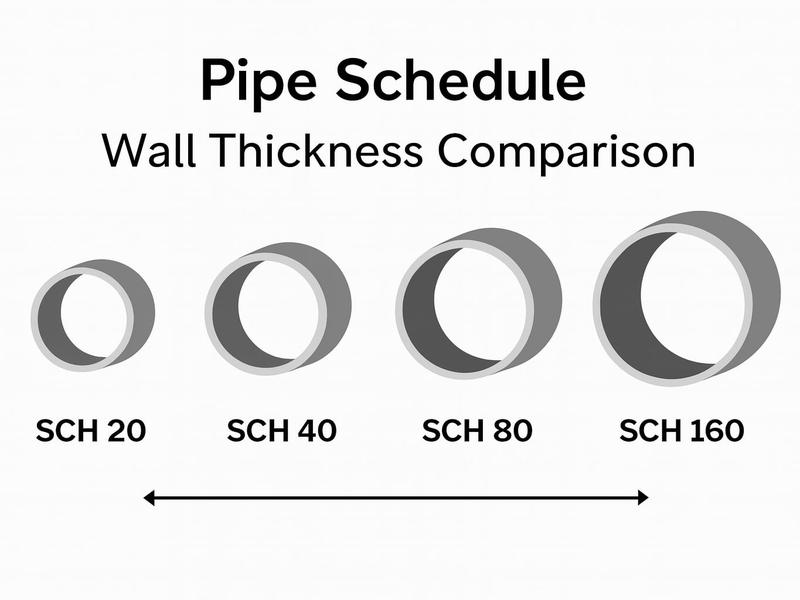

The dimensions of steel pipe directly determine their compatibility, flow performance, pressure-bearing capacity, and connection standards.

Understanding steel pipe dimensions can be confusing—OD, ID, NPS, DN, pipe size dimension chart...

If you have ever felt confused about material selection, this article will clarify all the key concepts for you.

Before Everything: Understanding Diameter

To fully understand OD, ID, and other pipe dimensions, we must start with the basic concept of diameter.

What Is Diameter?

For any circular shape, including round-shaped pipe ends, the diameter is measured as the distance between the two widest points, and the straight line must pass through the center of the circle.

In simple terms:

Diameter = the widest distance across a circle, passing through the center.

This applies to both outer diameter (measured across the external surface) and inner diameter (measured across the inner wall).

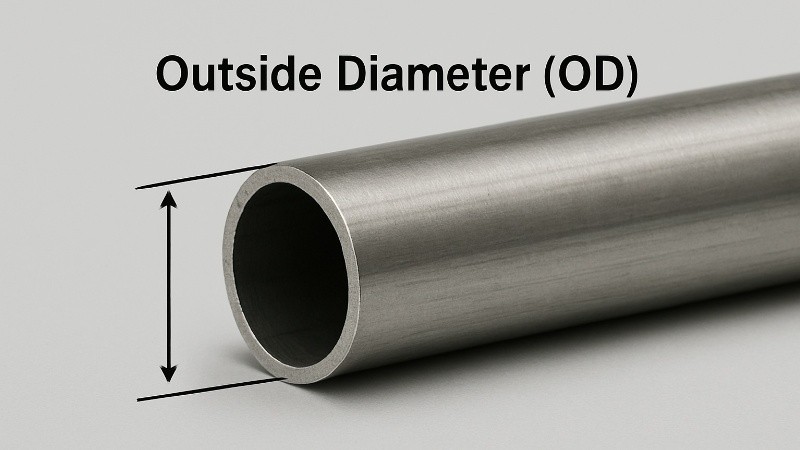

Outside Diameter (OD) and Why Does It Matter

When measuring the outside diameter, you need to cross the center of the round end of the pipe to extend a line to the two ends on the outside widest edge of the pipe. It is a fixed dimension that remains constant regardless of the wall thickness. OD is critical for pipe fittings, threading, welding compatibility, and overall system design.

The outer diameter plays a crucial role in ensuring compatibility with threading, fittings, welding, and the overall design of connections.

In short, OD is the first dimension you must match when selecting pipe fittings or connectors.

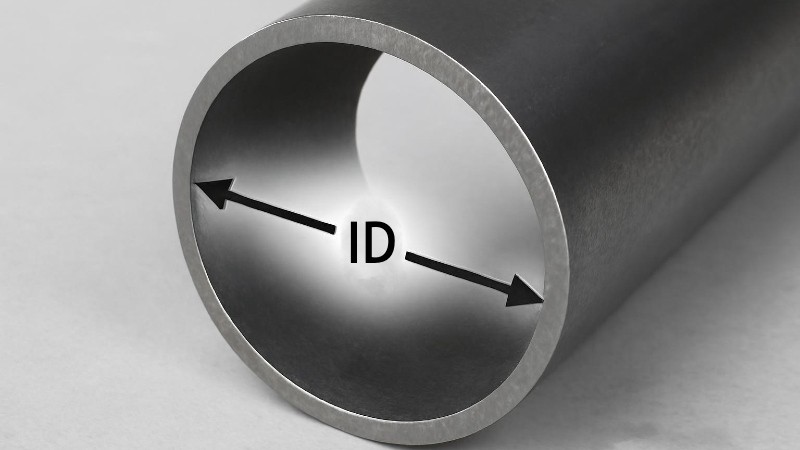

Understanding Inside Diameter

The inside diameter is the length of the diameter of the inner wall, a line crossing the pipe center point, both ends connected to the two inside widest points of the pipe. This length is the inner diameter.

Unlike the outside diameter, the inside diameter changes according to wall thickness. A thicker wall results in a smaller inner diameter of the pipe, while a thinner wall increases the inner diameter. ID plays a key role in calculating flow rate, pressure loss, and fluid capacity.

The inside diameter (ID) measures the usable space in the pipe.

Sizing pipes for water, gas, HVAC, or industrial fluid systems, ID is often the most important performance dimension.

Nominal Pipe Size (NPS) & Diameter Nominal (DN)

This is where things get interesting.

NPS (Nominal Pipe Size) in the imperial system and DN (Diameter Nominal) in the metric system are named sizes—not actual measurements.

They don’t match the OD or ID directly.

They’re basic labels used to standardize pipe sizes, making it easier for engineers and buyers to communicate.

Think of NPS/DN like T-shirt sizes:

“S”, “M”, “L”… the number doesn’t tell you the exact chest width, but everyone knows what size it refers to.

Key Differences

| Parameter | Actual Measurement | Changes With Wall Thickness | Primary Use |

|---|---|---|---|

| OD (Outside Diameter) | Yes | No | Fittings, threading, pipe connections |

| ID (Inside Diameter) | Yes | Yes | Flow rate, fluid capacity, pressure loss |

| NPS/DN (Nominal Diameter) | No | No | Standardized naming & specification |

Pipe Size Chart

| Nominal Pipe Size | Outside Diameter (mm) | Nominal Wall Thickness (mm) | |||||||||

| NPS (inch) | DN | ASME | JIS | DIN | Sch 10 | Sch 20 | Sch 40 | XS | Sch 80 | Sch 160 | XXS |

| 1/8" | 6 | 10.3 | 10.5 | 10.3 | 1.25 | 1.73 | 3.07 | 3.07 | |||

| 1/4" | 8 | 13.7 | 13.8 | 13.7 | 1.65 | 2.24 | 3.33 | 3.33 | |||

| 3/8" | 10 | 17.1 | 17.3 | 17.1 | 1.65 | 2.31 | 3.56 | 3.56 | |||

| 1/2" | 15 | 21.3 | 21.7 | 21.3 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | |

| 3/4" | 20 | 26.7 | 27.2 | 26.9 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | |

| 1" | 25 | 33.4 | 34.0 | 33.7 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | |

| 1-1/4" | 32 | 42.2 | 42.7 | 42.4 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | |

| 1-1/2" | 40 | 48.3 | 48.6 | 48.3 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | |

| 2" | 50 | 60.3 | 60.5 | 60.3 | 2.77 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | |

| 2-1/2" | 65 | 73 | 76.3 | 76.1 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | |

| 3" | 80 | 88.9 | 89.1 | 88.9 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | |

| 3-1/2" | 90 | 101.6 | 101.6 | - | 3.05 | 5.74 | 8.08 | 8.08 | |||

| 4" | 100 | 114.3 | 114.3 | 114.3 | 3.05 | 6.02 | 8.56 | 8.56 | 13.49 | 17.12 | |

| 5" | 125 | 141.3 | 139.8 | 139.7 | 3.4 | 6.55 | 9.53 | 9.53 | 15.88 | 19.05 | |

| 6" | 150 | 168.3 | 165.2 | 168.3 | 3.44 | 4.5 | 7.11 | 10.97 | 10.97 | 18.26 | 21.95 |

| 8" | 200 | 219.1 | 216.3 | 219.1 | 3.76 | 6.35 | 8.18 | 12.70 | 12.70 | 23.01 | 22.23 |

| 10" | 250 | 273 | 267.4 | 273 | 4.19 | 6.35 | 9.27 | 12.70 | 15.09 | 28.58 | 25.40 |

| 12" | 300 | 323.8 | 318.5 | 323.9 | 4.57 | 6.35 | 10.31 | 12.70 | 17.48 | 33.32 | 25.40 |

| 14" | 350 | 355.6 | 355.6 | 355.6 | 6.35 | 7.92 | 11.13 | 12.70 | 19.05 | 35.71 | |

| 16" | 400 | 406.4 | 406.4 | 406.4 | 6.35 | 7.92 | 12.70 | 12.70 | 21.44 | 40.49 | |

| 18" | 450 | 457.2 | 457.2 | 457 | 6.35 | 7.92 | 14.27 | 12.70 | 23.83 | 45.24 | |

| 20" | 500 | 508 | 508.0 | 508.0 | 6.35 | 9.53 | 15.09 | 12.70 | 26.19 | 50.01 | |

| 22" | 550 | 558.8 | 558.8 | - | 6.35 | 9.53 |

| 12.70 | 28.58 | 53.98 | |

| 24" | 600 | 609.6 | 609.6 | 610.0 | 6.35 | 9.53 | 17.48 | 12.70 | 30.96 | 59.54 | |

| 26" | 650 | 660.4 | 660.4 | - | 7.92 | 12.70 | 12.70 | ||||

| 28" | 700 | 711.2 | 711.2 | 711.0 | 7.92 | 12.70 | 12.70 | ||||

| 30" | 750 | 762 | 762 | - | 7.92 | 12.70 | 12.70 | ||||

| 32" | 800 | 812.8 | 812.8 | 813.0 | 7.92 | 12.70 | 17.48 | 12.70 | |||

| 34" | 850 | 863.6 | 863.6 | - | 7.92 | 12.70 | 17.48 | 12.70 | |||

| 36" | 900 | 914.4 | 914.4 | 914.0 | 7.92 | 12.70 | 19.05 | 12.70 | |||

| 38" | 950 | 965.2 | 965.2 | - | 12.70 | ||||||

| 40" | 1000 | 1016 | 1016 | 1016 | 12.70 | ||||||

| 42" | 1050 | 1066.8 | 1066.8 | - | 12.70 | ||||||

| 44" | 1100 | 1117.6 | 1117.6 | - | 12.70 | ||||||

| 46" | 1150 | 1168.4 | 1168.4 | - | 12.70 | ||||||

| 48" | 1200 | 1219.2 | 1219.2 | 1220.0 | 12.70 | ||||||