Full Range of Pipe Fittings We Manufacture

We manufacture a complete catalog of pipe fittings, including:

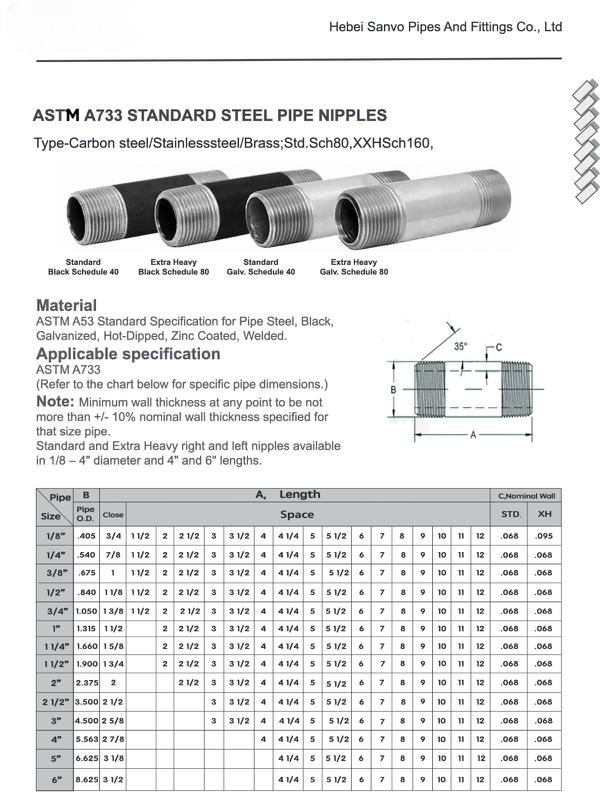

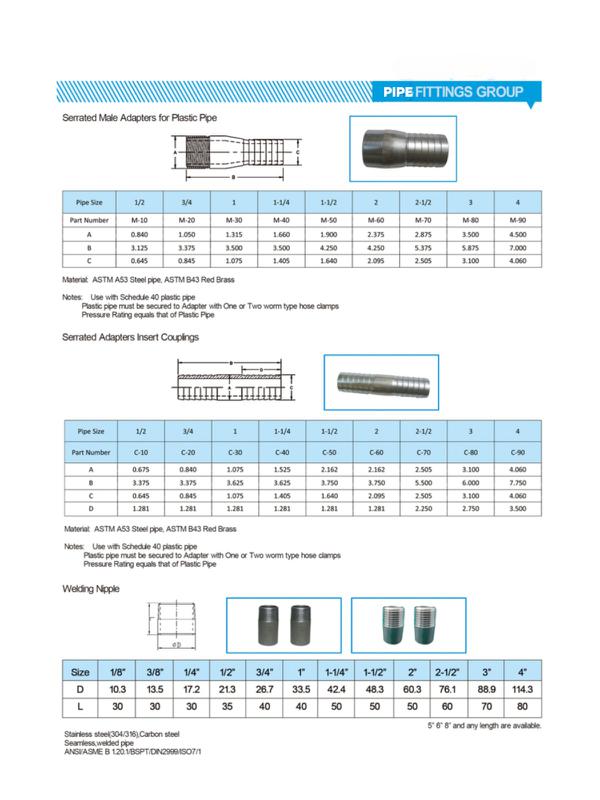

1. Pipe Nipples

Pipe nipples are short, threaded pipe connectors with male (external) threads on one or both ends and a smooth central body. Different types include:

-

A standard pipe nipple is a straight nipple with male threads on both ends, commonly used for oil, gas, and water pipelines.

-

A hex nipple features a hexagonal section in the middle for easy tightening with a wrench, ideal for high-pressure and industrial systems.

-

The hose nipple is designed with barbed or ribbed ends for connecting hoses to threaded piping systems, which are commonly used in fluid transfer and irrigation applications.

-

King Nipple is A heavy-duty nipple with longer threads, commonly used in suction or discharge hoses for oil, water, and air lines.

(Click size chart to download the PDF)

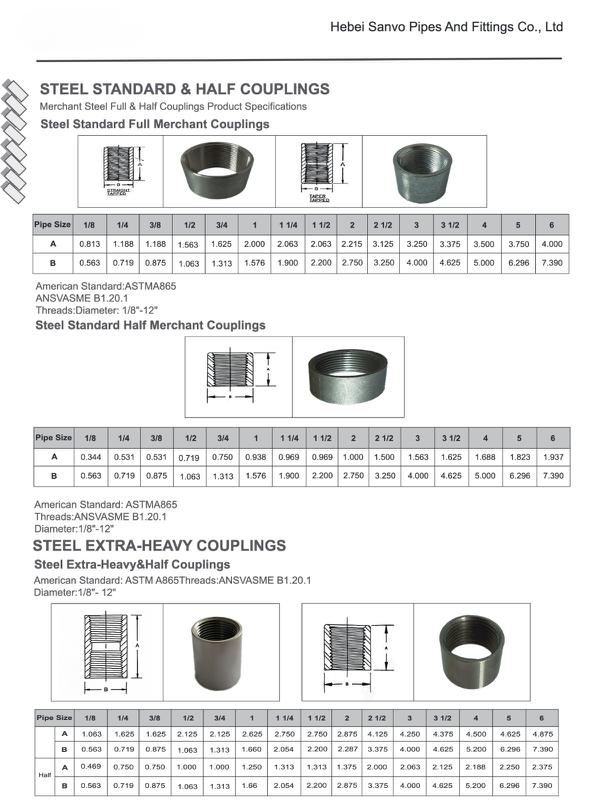

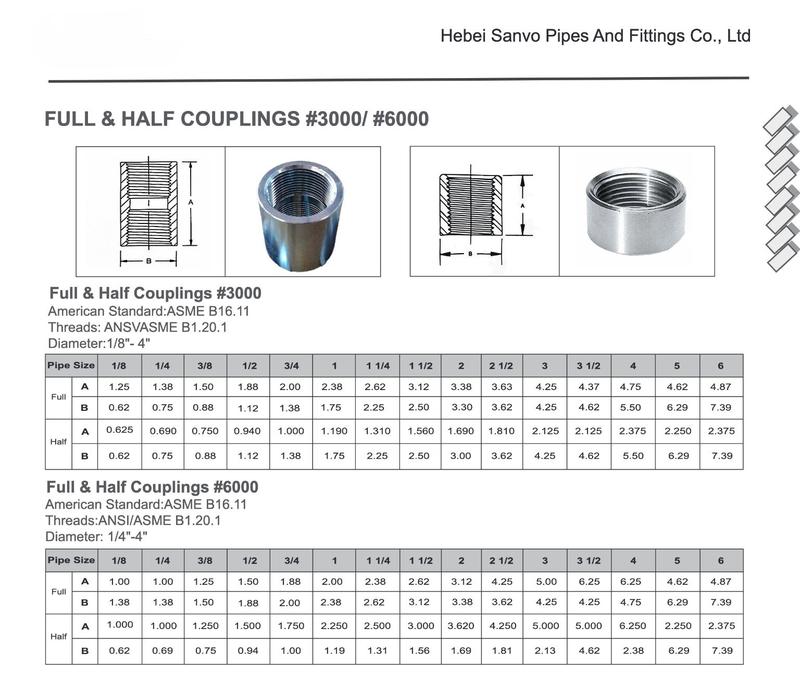

2. Pipe Sockets/Couplings

The pipe socket is a short cylinder pipe (with female threads) used to connect two pipes in a straight line. Main types include:

-

Standard couplings refer to those that have the same diameter on both ends, featuring female threads or socket-weld connections.

-

Reducer couplings connect different diameters they allowing for a smooth transition in flow between large and small pipes.

3. Pipe Elbows

Pipe elbows are fittings used to change the direction of flow in a piping system, typically at angles of 45° or 90°. They are essential in routing pipelines around obstacles or in confined spaces.

-

The 90-degree elbow is the most common type, used to create a sharp right-angle turn in pipelines. Suitable for water supply, gas systems, and industrial flow networks.

-

A 45-degree elbow provides a smoother directional change, reducing pressure loss and turbulence in fluid systems, often used in HVAC and plumbing installations.

-

Street Elbow has one end with male threads and the other with female threads, allowing for connection without the need for coupling. It simplifies installation in tight or awkward positions.

4. Pipe Tees & Crosses

Pipe Tees – T-shaped fittings that split or combine fluid flow; available in equal tees and reducing tees.

Pipe Crosses – Four-way fittings that connect pipes in cross-shaped configurations.

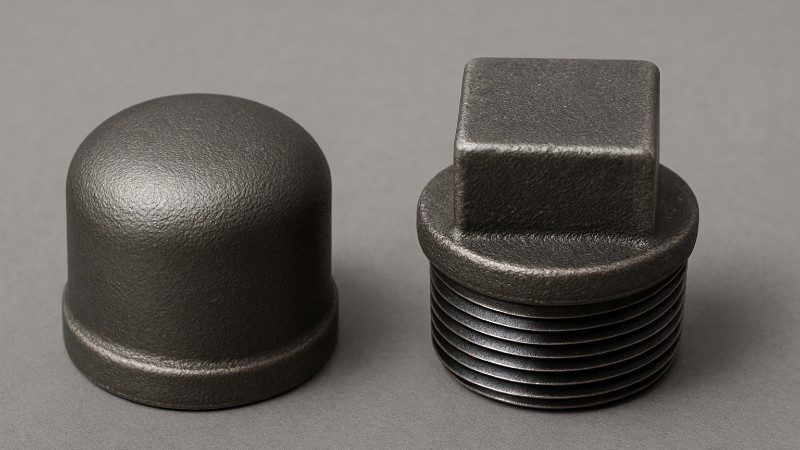

5. Pipe Caps & Pipe Plugs

Pipe Caps – Dome-shaped fittings that cover the end of a pipe to stop the flow or protect threads.

Pipe Plugs – Solid threaded plugs inserted into a fitting to seal off a pipe opening; available in hex, square, or round head designs.

6. Pipe Unions

Pipe Unions – Three-piece fittings (two end pieces and a central nut) designed for easy disassembly and maintenance of pipelines.

7. Valves

Valves regulate or stop fluid flow in plumbing and industrial systems. Common types include:

Gate Valves – For on-off flow control.

Ball Valves – Quick shut-off with a quarter-turn operation.

Check Valves – Prevent backflow in pipelines.

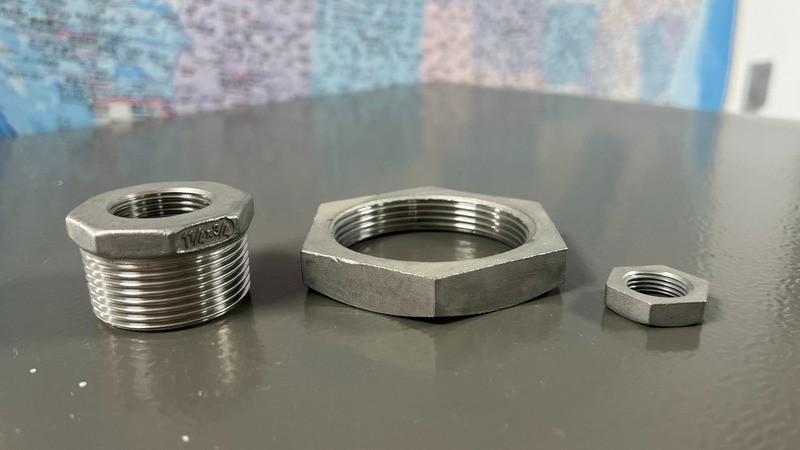

8. Hex Bushings & Lock Nuts

Hex Bushings – Threaded fittings that reduce the size of a pipe opening; the hex body allows wrench tightening.

Lock Nuts – Secure threaded fittings, preventing loosening due to vibration.

9. Flanges

Flanges – Flat, disc-shaped components bolted together for connecting pipes, valves, or pumps; available in slip-on, weld neck, and threaded types.

Pipe Fittings Materials Guide

-

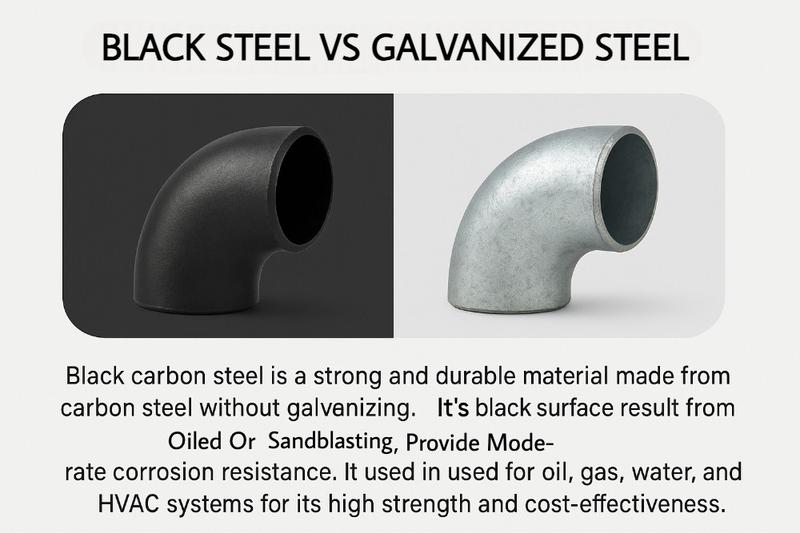

Galvanized Carbon Steel Pipe Fittings

Galvanized carbon steel pipe fittings are carbon steel fittings coated with a protective layer of zinc through a hot-dip or electro-galvanizing process. This zinc coating protects against moisture and oxygen, significantly slowing down and preventing rust corrosion.

Best Applications

Outdoor Plumbing & Water Supply Lines

Low to Medium-Pressure Systems

Construction & Structural Support

Advantages

Strong corrosion resistance in humid or outdoor environments

Cost-effective compared to stainless steel

Long service life with minimal maintenance

Limitations

Not suitable for high-temperature or high-pressure gas lines

Zinc coating can peel or wear off over time in highly abrasive environments

Common Question

Q: Are galvanized fittings safe for drinking water?

A: Yes, if lead-free zinc coating is used, they are safe for potable water.

Q: Can galvanized fittings be used for gas?

A: Not recommended due to flaking risk in gas systems.

-

Black Carbon Steel Pipe Fittings

Black carbon steel pipe fittings coated on the surface with oil or sandblasted to protect against corrosion, then have a black finish. They are designed to withstand high pressure and temperature.

Best Applications

Oil & Gas Pipelines

High-Pressure Industrial Systems

Indoor Use

Advantages

Excellent strength and durability under high pressure

More affordable than stainless steel fittings

Ideal for industrial and mechanical applications

Limitations

Prone to rust in humid or wet conditions

Not suitable for drinking water or food-related applications

Common Question

Q: Can black steel fittings be used for water?

A: Only for non-potable water; not recommended for potable water due to rust.

Q: What’s the pressure rating of black steel fittings?

A: Typically up to 150 psi for standard fittings, higher for specialized types.

-

Stainless Steel Pipe Fittings

Stainless steel pipe fittings are made from alloys containing chromium (at least 10.5%), which forms a passive layer that resists corrosion. Common grades include 304, 304L, 316, and 316L, with 316 offering superior corrosion resistance in chemical environments.

Best Applications

Chemical Processing & Food Industry

Water Treatment & Marine Systems

High-Pressure & Sanitary Systems

Advantages

Superior corrosion and rust resistance, even in harsh environments

Long service life with minimal maintenance

High strength and excellent aesthetic appearance

Limitations

Higher cost compared to galvanized or black steel

Heavier than plastic or brass fittings in some applications

Common Searches Answered

Q: Which is better, stainless or galvanized pipe fittings?

A: Stainless is better for corrosion resistance and sanitary use, while galvanized is cheaper and sufficient for general water systems.

Q: What grade of stainless steel fittings should I choose?

A: 304 for general plumbing, 316 for chemical and marine environments.

Applications of Our Pipe Fittings

Our pipe fittings are widely used in:

-

Plumbing & Water Supply Systems

-

Oil & Gas Pipelines

-

Firefighting & HVAC Systems

-

Industrial & Chemical Processing Equipment

Why Choose Us

-

OEM & ODM support for customized fittings

-

Advanced manufacturing facilities and strict quality control

-

International certifications: ISO, CE

-

Fast delivery and competitive prices for bulk orders

Contact Us for Bulk Orders

Looking for a reliable pipe fittings supplier in China?

Contact us today for bulk orders or OEM projects.