Technologies of Grooved Piping

Groove technology is a type of piping connection through process grooving on the pipe ends, and specially grooved couplings to the piping system connection.

-

The grooved ends are formed by rolling or cutting.

-

Grooved couplings are produced from steel and have an installed internal sealing ring to ensure sealing and leakproofness of the piping system.

-

The worker needs to insert the pipe ends into the connectors and tighten the bolt to complete the connection without welding or the threading process when installing.

Principal Advantages

-

Faster installation and saves 50% to 70% time than a welding connection.

-

Convenient for maintenance due to fast removal and replacement design.

-

The seal ring can reliably prevent leaks.

-

Higher safety.

-

Connected by grooved couplings can reduce noise.

-

Grooved coupling, small size, and tightened to save space.

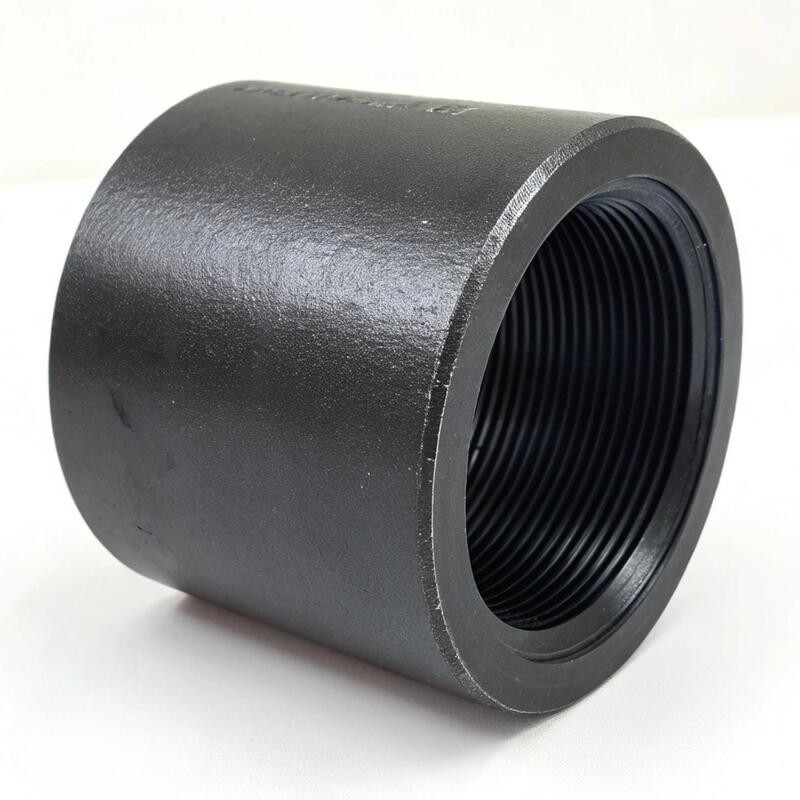

Common Grooved Fittings

The grooved pipe is typically not used on its own; it requires compatible grooved fittings to create complete piping systems. They are common types of grooved fittings below:

-

Grooved Coupling

-

Grooved Elbow

-

Grooved Tees & Cross

-

Grooved Flange

The "grooved end pipe + grooved pipe fittings" are the components of the grooved piping system, which achieve complete piping systems by using different types of grooved pipe fittings. The grooved system is installed quickly, safely, reliably, and easily maintained.

Pressure Class of Grooved End Pipe

The pressure class of grooved end pipes and grooved fittings depends on pipe material, wall thickness, diameter, and the types of grooved pipe fittings.

The common pressure range of the grooved end pipe is 150 to 600 psi.

Main Standards for Grooved Pipes & Fittings

Grooved pipe and fittings have production and test standards unified internationally. Different regions have a few differences, but core content includes size, tolerance, grooved profile, connection perforation, and pressure requirement.

-

AWWA C606 was developed by the American Water Works Association, which specifies groove sizes, tolerances, grooved depth, sealing ring requirements, and testing methods. It is the most commonly used in America for fire protection, HVAC, and industrial piping systems.

-

ASTM A795 and ASTM A53 specify sizes and performance standards that are typically used in conjunction with AWWA C606.

-

ISO 6182-12 / ISO 4200 are standards developed by the International Organization for Standardization (ISO) to outline the technical requirements for grooved pipe fittings. These requirements encompass mechanical strength, sealing performance, and pressure-resistant classifications. Grooved fittings are commonly used in Europe, Southeast Asia, the Middle East, and various international markets.

-

The European Committee for Standardization developed EN 10226 / EN 10255, which are suitable for the European Union and European markets.

-

UL Listed and FM Approved products, developed by Underwriters Laboratories and Factory Mutual, are designed for grooved pipes and fittings used in fire sprinkler systems. This certification ensures that the products have undergone structural, pressure, and corrosion testing. Only those products that have completed UL/FM certification can be utilized in fire protection projects across North America.