What is the difference between seamless and welded steel pipes? From their definition, we can see that one has no gaps and the other has gaps. And the seamless steel pipe can be seen from the outer surface, there is no gap in the whole body; the welded steel pipe has a welding gap. The price of seamless steel pipes is generally higher than that of welded steel pipes. Seamless steel pipes are generally used in factories; welded steel pipes are generally used in construction. The pressure resistance of seamless steel pipes is higher than that of welded steel pipes.

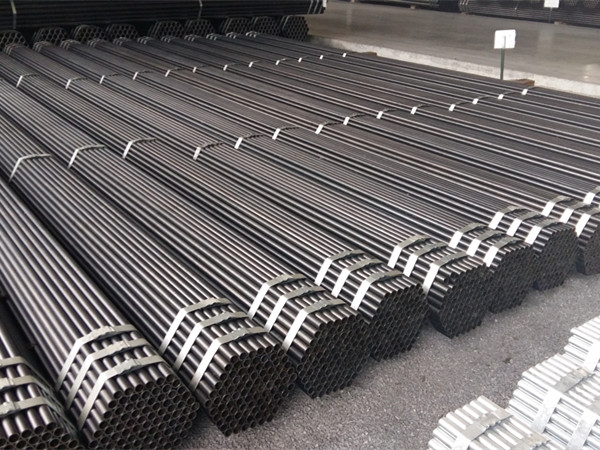

1. Seamless Steel Pipe Definition

Seamless steel pipes are perforated from whole round steel, and steel pipes without welds on the surface are called seamless steel pipes. According to the production method, seamless steel pipes can be divided into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, extruded seamless steel pipes, and top pipes. According to the cross-sectional shape, seamless steel pipes are divided into two types: round and special-shaped. Special-shaped pipes have square, elliptical, triangular, hexagonal, melon-shaped, star-shaped, and finned pipes. The maximum diameter is 900mm and the minimum diameter is 4mm. According to different uses, there are thick-walled seamless steel pipes and thin-walled seamless steel pipes. Seamless steel pipes are mainly used as petroleum geological drilling pipes, cracking pipes for the petrochemical industry, boiler pipes, bearing pipes, and high-precision structural steel pipes for automobiles, tractors, and aviation.

Seamless Steel Pipe Use/Application

(1) General-purpose seamless steel pipes are rolled from ordinary carbon structural steel, low-alloy structural steel, or alloy structural steel, with the largest output, and are mainly used as pipelines or structural parts for conveying fluids.

(2) There are three types of supply according to different purposes:

a. Supply according to chemical composition and mechanical properties;

b. According to mechanical performance;

c. According to the water pressure test supply.

Note: Steel pipes supplied according to categories a and b, if used to withstand liquid pressure, must also undergo a hydraulic test.

(3) Special-purpose seamless pipes include seamless pipes for boilers, chemical and electric power, seamless steel pipes for geology, and seamless pipes for petroleum.

Seamless steel pipes have a hollow section and are used in large quantities as pipelines for conveying fluids, such as pipelines for conveying oil, natural gas, gas, water, and certain solid materials. Compared with solid steel such as round steel, steel pipe has a lighter weight when the bending and torsion strength is the same, and it is economical section steel.

Widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, bicycle frames, and steel scaffolds used in construction. Steel pipes are used to make ring parts, which can improve material utilization, simplify manufacturing procedures, and save materials and processing. Working hours, steel pipes have been widely used for manufacturing.

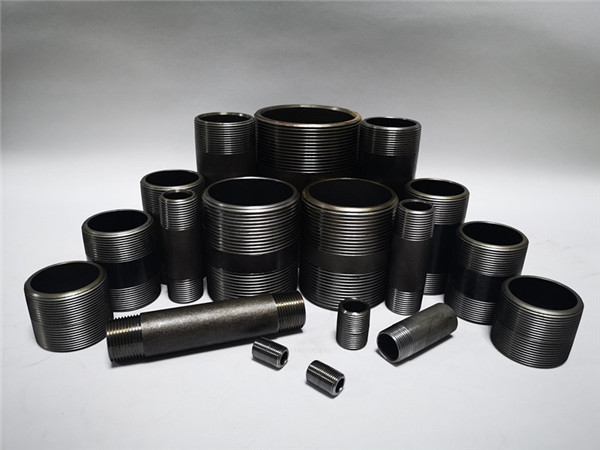

2. Welded Steel Pipe Definition

Welded steel pipes refer to steel pipes with seams on the surface that are welded after bending and deforming steel strips or steel plates into round or square shapes. The blanks used for welded steel pipes are steel plates or strip steels.

Since the 1930s, with the rapid development of high-quality strip, continuous rolling production, and the advancement of welding and inspection technology, the quality of welds has been continuously improved, and the variety and specifications of welded steel pipes have increased and replaced seamless steel pipes in more and more fields. Welded steel pipes have lower costs and higher production efficiency than seamless steel pipes.

Classification Method Of Welded Steel Pipe

(1) According to different welding methods, it can be divided into arc welded pipe, high frequency or low-frequency resistance welded pipe, gas welded pipe, furnace welded pipe, Bondi pipe, etc.

- Electric welded steel pipe: used in oil drilling and machinery manufacturing.

- Furnace welded pipes: can be used as water gas pipes, etc., large-diameter longitudinally welded pipes are used for high-pressure oil and gas transportation, etc.; spiral welded pipes are used for oil and gas transportation, pipe piles, bridge piers, etc.

(2) According to the weld shape, it can be divided into straight seam welded pipe and spiral welded pipe.

- Longitudinal welded pipe: The production process is simple, the production efficiency is high, the cost is low, and the development is fast.

- Spiral welded pipe: The strength is generally higher than that of straight seam welded pipes. A narrower blank can be used to produce welded pipes with larger pipe diameters, and a billet with the same width can also be used to produce welded pipes with different pipe diameters. But compared with the straight seam pipe of the same length, the weld length is increased by 30-100%, and the production speed is lower. Therefore, most of the smaller diameter welded pipes adopt straight seam welding, and the large diameter welded pipes mostly adopt spiral welding.

(3) According to the purpose, it is divided into general welded pipe, galvanized welded pipe, oxygen-blowing welded pipe, wire casing, metric welded pipe, roller pipe, deep well pump pipe, automobile pipe, transformer pipe, electric welded thin-walled pipe, electric welded special-shaped pipe, and spiral welded pipe.

(4) According to the shape of the end, it is divided into round welded pipe and special-shaped (square, flat, etc.) welded pipe.

(5) Other Categories

- GB/T3091-1993 (Galvanized welded steel pipe for low-pressure fluid transportation). Mainly used to transport water, gas, air, oil, heating hot water or steam, and other generally lower pressure fluids and other purposes. Its representative material is Q235A grade steel.

- GB/T3092-1993 (Galvanized welded steel pipe for low-pressure fluid transportation). Mainly used for conveying water, gas, air, oil, heating hot water or steam, and other generally lower pressure fluids and other purposes. Its representative material is Q235A grade steel.

- GB/T14291-1992 (Welded steel pipe for mining fluid transportation). Mainly used for straight seam welded steel pipes for mine pressure, drainage, and shaft gas discharge. Its representative material is Q235A, Grade B steel. GB/T14980-1994 (Large diameter electric welded steel pipe for low-pressure fluid transportation). It is mainly used to transport low-pressure fluids such as water, sewage, gas, air, heating steam, and other purposes. Its representative material is Q235A grade steel.

- GB/T12770-1991 (stainless steel welded steel pipe for mechanical structure). Mainly used in machinery, automobiles, bicycles, furniture, hotel and restaurant decoration, and other mechanical parts and structural parts. Its representative materials are 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb, etc.

- GB/T12771-1991 (Stainless steel welded steel pipe for fluid transportation). Mainly used to transport low-pressure corrosive media. Representative materials are 0Cr13, 0Cr19Ni9, 00Cr19Ni11, 00Cr17, 0Cr18Ni11Nb, 0017Cr17Ni14Mo2, etc.

3. Seamless And Welded Pipe Difference

(1) Different In Nature

a. Seamless steel pipe: a steel pipe made of a single piece of metal with no seams on the surface.

b. Welded steel pipes: steel strips or steel plates that are bent and deformed into round or square shapes and then welded into steel pipes with seams on the surface.

(2) The Characteristics Are Different

a. Seamless steel pipe: the maximum diameter is 650mm, and the minimum diameter is 0.3mm. According to different uses, there are thick-walled pipes and thin-walled pipes.

b. Welded steel pipes: T-welded steel pipes have strong corrosion resistance in acidic environments when they contain Ni. In environments containing sulfuric acid or hydrochloric acid, the higher the Ni content in the T-welded steel pipes, the stronger the corrosion resistance. Under normal circumstances, only adding Cr to the T-welded steel pipe can prevent corrosion.

(3) The Role Is Different

a. Seamless steel pipes: seamless steel pipes are mainly used as petroleum geological drilling pipes, cracking pipes for petrochemicals, boiler pipes, bearing pipes, and high-precision structural steel pipes for automobiles, tractors, and aviation.

b. Welded steel pipes: electric welded steel pipes are used in oil drilling and machinery manufacturing, etc.; furnace welded pipes can be used as water gas pipes, and large-diameter longitudinally welded pipes are used for high-pressure oil and gas transportation; spiral welded pipes are used for oil and gas transportation, pipe piles, bridge piers, etc.