Brass is a copper alloy with a mixture of copper and zinc, and occasionally other metals. Stainless steel is an iron alloy mixed with chromium and nickel. While a more expensive option than brass, steel is a very durable, resilient metal. Steel is also able to work in more temperatures than brass and tends to last longer. Both stainless steel ball valve and brass ball valve are corrosion resistant, but stainless steel ball valves are the best options for high pressure and temperature situations.

Ball Valves are a very popular product used in the Plumbing industry. They can stop the flow of water coming through the line. There are 2 main material types for metal Ball Valves. Brass and Stainless Steel. With the growing popularity of stainless fittings in non-industrial applications, Stainless Steel Ball Valves continue to gain more attention.

1. What Are Stainless Steel Ball Valves?

The stainless steel ball valve can be closed tightly with only a 90-degree rotation and a small torque. The completely equal internal cavity of the valve provides a straight flow channel with little resistance for the medium. The main feature of the ball valve is its compact structure, easy to operate and maintain. The stainless steel ball valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal, and radioactive media. The ball valve body can be integral or combined. This type of valve should generally be installed horizontally in the pipeline. The two most commonly used materials for stainless steel ball valves are 304 and 316.

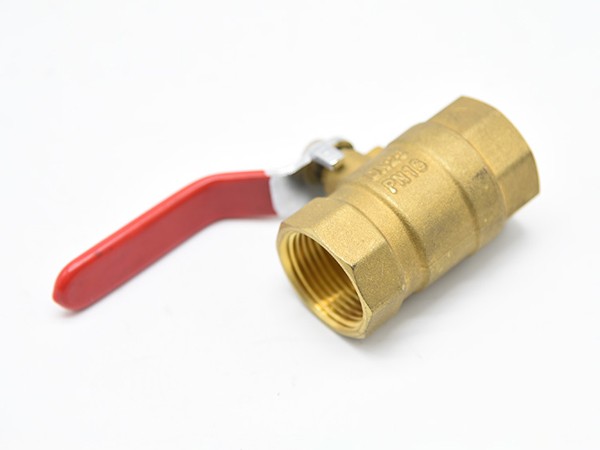

2. What Are Brass Ball Valves?

Brass ball valves are some of the most common types that you will utilize in plumbing, water well, etc. They are fairly easy to work with and install, and suit many applications where corrosion resistance is not a big issue. Brass ball valves are easy to work with and install. By easy to work with, I mean that brass as a material is softer than others (like stainless steel), this makes sealing them easier. Also due to the popularity of brass valves, the products that are used for sealing them are very readily available. When sealing other types of metals, you often need a specific pipe tape or thread sealant. Not that these are impossible to find, but you are more apt to find brass sealing products easier than others.

3. Applications For Stainless Steel Ball Valves

Because stainless steel ball valves are resistant to corrosion, high temperature, and high pressure, they are widely used in industrial, manufacturing, construction, and other pipelines.

Here are a few common application areas of stainless steel ball valves:

Petroleum Refining

It is a great example of a job that only stainless steel ball valves can do. Crude petroleum can contain water, carbon dioxide, sulfur, and all kinds of microorganisms. These make it a very corrosive substance. It will slowly break down metal over time, so you must get valves and pipes that will be able to withstand it for the longest amount of time. Stainless steel ball valves will hold up longer than other materials and because stainless steel ball valves are more resistant to corrosion, so they are the obvious choice.

Marine Operations

Some applications take place in or near seawater, such as desalination. Marine environments are corrosive and harmful to all types of materials, but because they involve water, they affect metals most of all. In these types of applications, many like to use plastic ball valves that may have better resistance to water and harsh chemicals than most metals. The problem with this is that plastic valves lack the ability to perform under high pressures and extreme temperatures. Stainless steel ball valves handle intense conditions with ease. And with the proper maintenance, a stainless ball valve can have a long lifespan around seawater.

Brewing Systems

Stainless steel ball valves are used in just about every brewery. Most commonly located on the kettle, stainless ball valves allow the user to control liquid flow during transfers. The reason stainless steel is necessary is it comes in direct contact with wort, the liquid extracted during the mashing process when brewing beer or whisky. This is a corrosive liquid substance that would wear down valves made of iron. Since ball valves of other materials (such as brass ball valves) can't handle the temperatures encountered in brewing, stainless steel ball valves are the best option.

4. Applications For Brass Ball Valves

Brass ball valves can be used in a wide range of applications. Most of the time, brass is a great option. When it comes to potable water applications, No-Lead Brass is a great option unless that water has corrosive properties to it, like seawater(high salt content). In that case, another material like stainless would work better. Because of the cost of No-Lead Brass, other materials like stainless, which is also No-Lead, have become more possible options.

Brass ball valves are used in residential and commercial plumbing, water well, HVAC, and many other applications. Basically, as long as there are no high corrosive properties in what is going through the valves, generally speaking, brass is a great material to utilize.

5. Difference Between Stainless Steel Ball Valves And Brass Ball Valves

- Material: The brass ball valve is a copper alloy with copper and zinc occasionally mixed with other metals, while the stainless steel ball valve is an iron alloy of chromium and nickel.

- Cost: When the No-Lead laws started coming into effect in many States and Provinces in North America, No-Lead Brass grew in popularity and the rise of No-Lead Brass pricing. The price of stainless steel ball valves is higher than that of leaded brass ball valves, but the price of lead-free brass ball valves is not much different. It is a good option of using No-Lead brass ball valves on non-potable water applications and this can save you a lot of money.

- FDA Approval: The FDA does not approve of brass ball valves unless they are certified lead-free, making them a poor choice for use in the food industry. Stainless steel ball valves, however, are approved by the FDA for use in the food industry.

- Softness: Brass is softer than stainless steel, which makes it easier to seal brass ball valves than stainless steel ball valves. And products for sealing brass ball valves are easier to obtain than products for sealing stainless steel ball valves. Because of its chemical makeup, brass is much better for welding than stainless steel. In order to use stainless steel for welding, you must often break down its oxide layer.

- Corrosion Resistance: Brass is able to withstand corrosion better than plastic. However, stainless steel is still the best in the corrosion resistance department, especially in marine environments. Stainless steel ball valves will hold up much better in a harsher water environment, and this will ensure a longer-lasting valve.

- Pressure Ratings: Generally speaking, stainless steel ball valves have higher pressure ratings than brass. For example, a standard brass ball valve might have a pressure rating of 600 PSI on a 1” model. A standard stainless ball valve would probably have a pressure rating of 1000 PSI on a 1” model. Therefore, stainless steel ball valves are more resistant to high pressure than brass ball valves.

- High-Temperature Resistance: Steel is also able to work in more temperatures than brass and tends to last longer. Stainless steel ball valves are the best options for high-temperature situations.

These factors should be considered when deciding on valve materials for your next project. Before choosing a valve for your product, be sure to conduct an in-depth study of your industry, needs, and materials of interest to you. And remember that if you want to have more corrosion resistance built into your system, you should be using a full stainless steel system.

SANVO is one of the quality stainless steel ball valve manufacturers and suppliers in China and exports 1/4"-4" and DN6-DN100 sizes 304/316 stainless ball valves. At the same time, SANVO is one of the quality steel pipes and fittings manufacturers, suppliers, exporters, wholesalers, factories, and companies in China, supplying carbon steel and stainless steel pipes, carbon steel and stainless steel pipe fittings, carbon steel and stainless steel pipe flanges, etc.

If you are interested in our pipeline products, please do not hesitate to contact us, we look forward to your news.