Welded Pipe Manufacturing Process

Welded steel pipes are produced by forming a steel coil or plate into a cylindrical shape through hot or cold rolling and welding. Welding and forming methods vary depending on the product.

After welding, pipes undergo internal and external seam trimming and smoothing, end conditioning (plain, grooved, or threaded), and anti-corrosion treatments such as oiling and galvanizing coating.

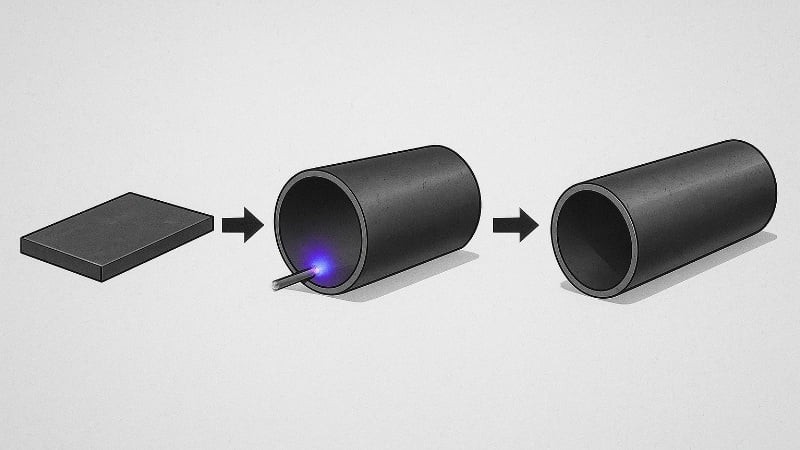

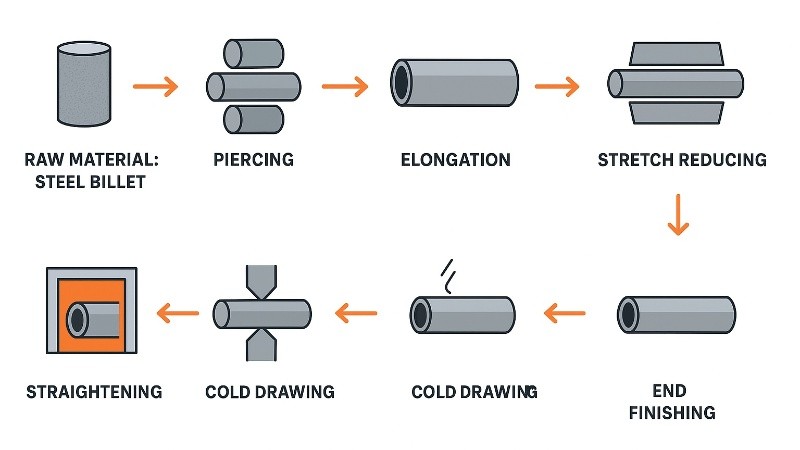

Seamless Pipe Manufacturing Process

Seamless steel pipes are produced without any welding seam. They are manufactured by piercing solid steel billets and forming them into hollow tubes through a series of thermal and mechanical processes. Seamless pipes provide superior strength, uniformity, and high-pressure resistance, making them essential in oil & gas, boilers, hydraulic systems, and high-temperature applications.

Seamless vs. Welded Pipe: Advantages and Disadvantages

Seamless Steel Pipe

Advantages

The seamless steel pipe without a weld seam has uniform strength throughout.

Ideal for high-pressure, high-temperature, and critical service conditions.

Uniform structure, high toughness, long-term service.

Suitable for precision and heavy-wall applications, such as hydraulic cylinders, boiler tubes, and oil & gas lines.

Disadvantages

The processes of complex manufacturing, piercing, rolling, and sizing make the seamless pipe more expensive.

More difficult to produce large diameters compared to welded pipes.

Compared to the welded pipe, the wall thickness tolerance can vary more.

Welded Steel Pipe

Advantages

Lower cost and higher production efficiency.

Smooth internal surface, Suitable for low- to medium-pressure fluid transport.

Wall thickness, diameter, and length can be tailored easily.

Disadvantages

Weld can be a weak point under very high pressure or extreme service conditions.

Not ideal for ultra-high-pressure applications, Seamless pipes perform better for boilers, hydraulic systems, and critical oil & gas operations.

Comparison Table

| Feature | Seamless Steel Pipe | Welded Steel Pipe |

|---|---|---|

| Weld Seam | None | Present |

| Strength & Pressure Resistance | Higher | Moderate, depends on weld quality |

| Mechanical Properties | Superior | Good, but affected by welding |

| Cost | Higher | Lower |

| Wall Thickness Uniformity | Slight variation | Very consistent |

| Ideal Applications | High pressure, high temperature, critical service | Low/medium pressure, structural, large-diameter pipelines |

Dimensions and Wall Thickness of Seamless vs. Welded Pipe

Common Dimensional Standards

We produce seamless steel pipes and welded Steel Pipes in NPS from 1/8 inch to 48 inches (DN 6 – DN 1200). Standards include ASTM A106, API 5L Gr. B, ASTM A53.

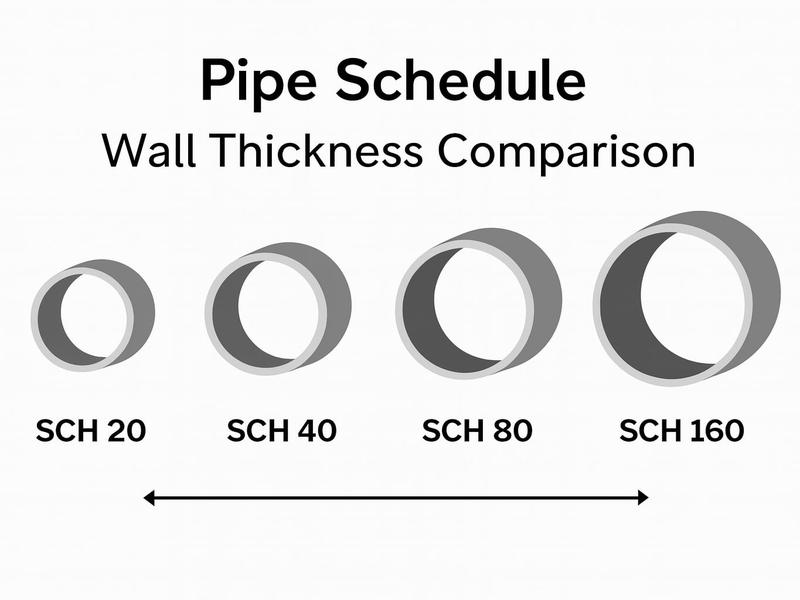

Pipe Schedule

We produce seamless pipes and welded steel pipes, which can achieve SCH 10, SCH 20, SCH 40, SCH 80, SCH 160, XS, and XXS.

Application Recommendations

- Seamless Pipes – Best For

High pressure, high temperature, or critical service

Thick-wall pipe requirements

Small-diameter precision tubing

Oil & gas, boilers, hydraulic systems, pressure vessels

- Welded Pipes – Best For

Large-diameter pipelines

Water supply, fire protection, and structural applications

Medium- and low-pressure systems

Stainless steel decorative tubing, thin-wall applications

Cost-sensitive projects

Pipe End Finishes for Welded and Seamless Pipes

Both welded and seamless steel pipes can be supplied with different end types depending on installation requirements, connection method, and industry standards. Below are the most common and engineering-approved end finishes.

Plain End (PE)

Pipe end is cut round with no additional machining.

Can be supplied deburrred, faced, or lightly chamfered

Features: Most economical, Simple processing, High versatility

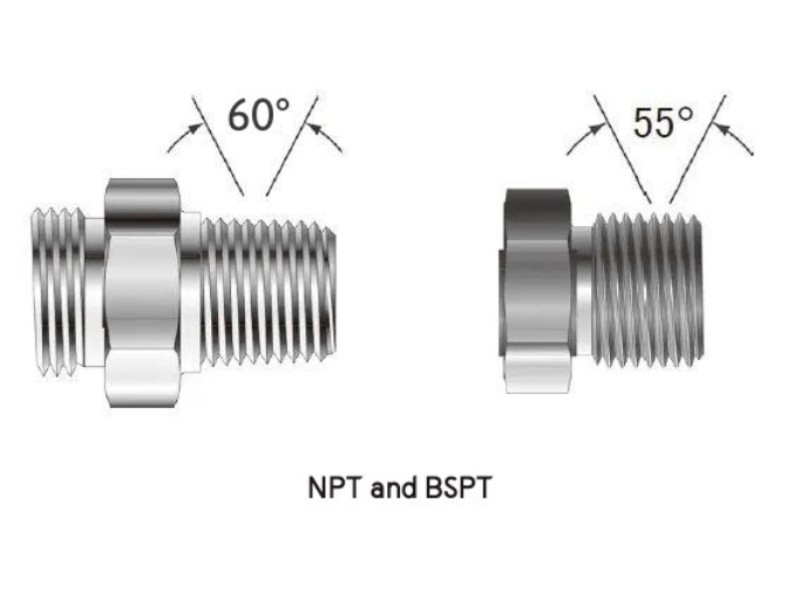

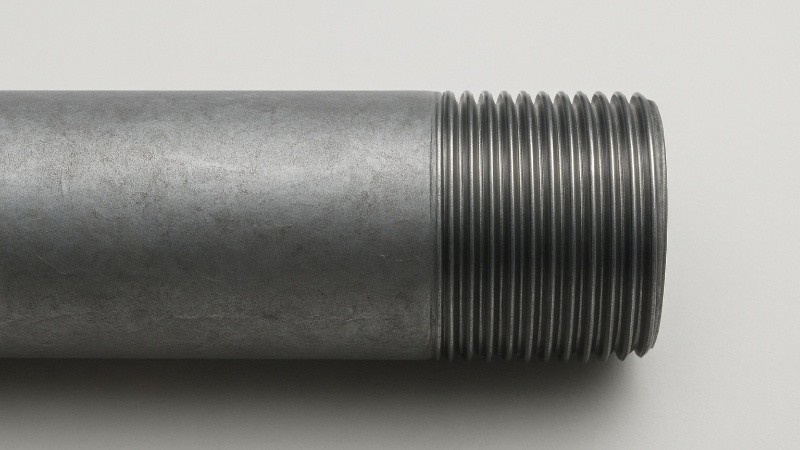

Threaded End (TE)

It can be used for both, but is more common in welded pipes.

Threads typically follow NPT, BSPT, or BSPP standards.

Usually with thread protector caps.

Thread options:

-

Male Thread

-

Female Thread (less common, usually used on fittings)

Note:

For seamless pipes, threading is also common for high-pressure fittings (e.g., ASTM A106 Gr.B).

Grooved End

Groove cut at pipe end for mechanical coupling systems (Victaulic groove type).

Used in: fire sprinkler systems, HVAC systems, low or medium-pressure water distribution

Advantages:

-

Fast installation

-

No welding needed on site

-

Easy maintenance

Flanged Ends

Pipe ends are prepared to connect with a flange.

Used for high-pressure service.

Conduit Ends (for threaded pipes)

Common for welded and seamless small-diameter pipes

Pipes supplied with one socket/coupling + one male thread

Standard for plumbing & fire protection pipes

Bell End

For socket-type joining, mostly for water pipes.

Key Considerations When Purchasing Seamless and Welded Steel Pipes

Material Standards & Specifications

Ensure the pipe grade meets the required international standards (e.g., ASTM, ASME, API, EN, DIN).

Seamless: ASTM A106, ASTM A53, API 5L Gr. B

Welded: ASTM A53, ASTM A312, API 5L Gr. B

Manufacturing Process

Different processes lead to different performance levels:

Seamless pipes: hot-rolled, cold-drawn, or cold-rolled.

Welded pipes: ERW, LSAW/SAW, SSAW, TIG-welded for stainless steel.

Pressure & Temperature Requirements

Seamless pipes generally perform better under high pressure, high temperature, or cyclic loading.

Welded pipes are suitable for medium- and low-pressure systems.

Choose the correct schedule (SCH) or wall thickness accordingly.

Corrosion Resistance Requirements

For corrosive environments, assess:

Material grade (e.g., 304/316 stainless, galvanized steel)

Surface finishing: hot-dip galvanizing, black sandblasted

Expected lifespan in the intended application

Request a quote

Sanvo stays fully stocked with the best inventory of welded and seamless steel piping products in the industry. We have a factory, ensuring buyers get the pipe they need faster and at the best price.

In this guide for buyers of seamless and welded pipe, we will help you navigate the procurement process from start to finish. We aim to ensure that you acquire what you need as quickly and efficiently as possible when it's time to make a purchase. If a piping purchase is in your near future, request a quote. We’ll provide one that gets you exactly the products you need—fast.